really nice TIG work there. I have welder's envy.

Fleet Fox

Fleet Fox

My plan was to run up to Lowe's and buy another roll but didn't get around to it for a few days because I'm off work and the number one and two things on my to-do list are napping and being lazy

My plan was to run up to Lowe's and buy another roll but didn't get around to it for a few days because I'm off work and the number one and two things on my to-do list are napping and being lazy  Unfortunately things need to get done and since "Eat huge breakfasts" is the number three thing on my to-do list and I used up all of the eggs making creme brulee we had to go to the store. We also had to do the last of the Christmas shopping and somehow our route took us right past Airgas. So instead of going to Lowe's I whipped in there and picked up a couple of spools of wire, which were actually cheaper than Lowe's. So today after a big breakfast and a nap I set to work once again on welding in the RH wheel well. That is actually going extremely well. I'm doing full seam welds instead of spot welds so it is taking a bit more time and effort than tack welds.

Unfortunately things need to get done and since "Eat huge breakfasts" is the number three thing on my to-do list and I used up all of the eggs making creme brulee we had to go to the store. We also had to do the last of the Christmas shopping and somehow our route took us right past Airgas. So instead of going to Lowe's I whipped in there and picked up a couple of spools of wire, which were actually cheaper than Lowe's. So today after a big breakfast and a nap I set to work once again on welding in the RH wheel well. That is actually going extremely well. I'm doing full seam welds instead of spot welds so it is taking a bit more time and effort than tack welds.

Santa will be coming off tomorrow.

Santa will be coming off tomorrow.

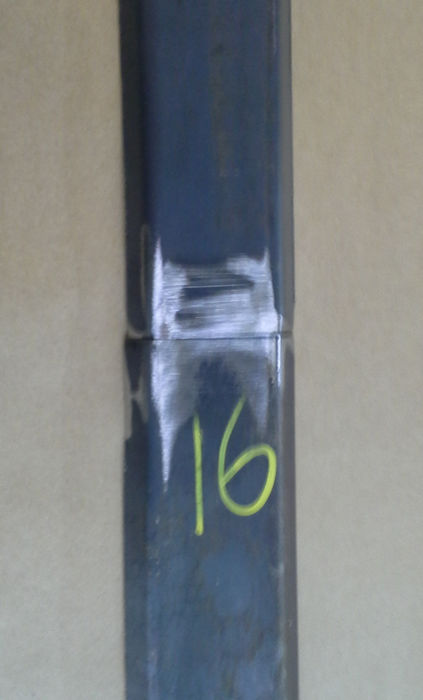

So another trip to airgas was in order on new years eve. I got that and finished all the welding and began grinding down the welds.

So another trip to airgas was in order on new years eve. I got that and finished all the welding and began grinding down the welds.

)

)

Comment