Part of the Howell kit involves rerunning some evap lines to the charcoal canister, so during inspection found I needed to replace some. Hard to tell but these are the evap hoses for the fuel tank and transmission, which were so brittle they had turned to powder, and one had a huge hole burned thru it at some point due to it resting on the passenger exhaust manifold. I cut new hoses and ran them differently than they were originally to keep away from hot areas:

PXL_20210501_171632035 by Robert Stone, on Flickr

PXL_20210501_171632035 by Robert Stone, on Flickr

Took forever to get the evap hoses out since I had to jack the passenger side up to get to the bolt that held the lines to the transmission. Once I got that bolt out I was able to wrangle the lines lower to remove the perma-clamps. Measured out new lengths, a bit longer to run them differently up the inner fender, and hose-clamped them to to the lines:

PXL_20210501_172147069 by Robert Stone, on Flickr

PXL_20210501_172147069 by Robert Stone, on Flickr

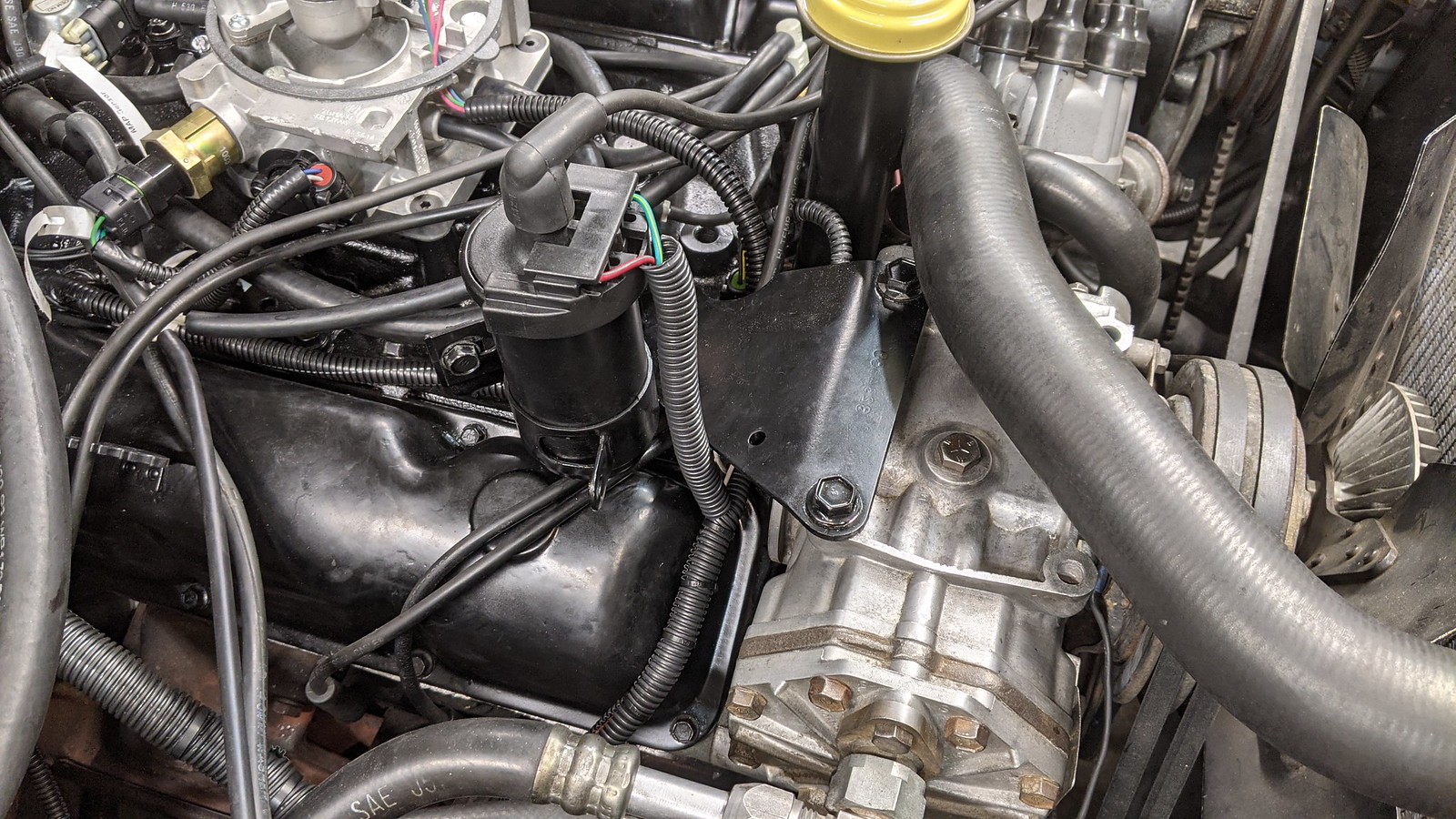

Took forever to get the passenger side #4 cylinder air injection hole drilled out and retapped to screw in the new manifold plug, but it's done now:

PXL_20210430_020316927 by Robert Stone, on Flickr

PXL_20210430_020316927 by Robert Stone, on Flickr

Part of the new fuel injection kit was getting a new O2 sensor hole drilled, bung welded up, and sensor screwed in. Local shop got that done for me. Was the first time I'd driven the beast on public roads more than a couple hundred feet. Placement was per Howell, in front of driver side pipe:

PXL_20210504_015137752 by Robert Stone, on Flickr

PXL_20210504_015137752 by Robert Stone, on Flickr

Also had the shop inspect the cat and as I figured it had been gutted and was useless, so had the shop weld up a new Magnaflow cat. Exhaust smells much better now!!:

PXL_20210503_222825088 by Robert Stone, on Flickr

PXL_20210503_222825088 by Robert Stone, on Flickr

Shop also removed the air injection pipe that went from driver side down to the original cat, with its custom water hose job. Unseen here was a large hole worn into the bottom of the pipe, making this thing useless even if everything else was good (which it wasn't!):

PXL_20210503_225117107 by Robert Stone, on Flickr

PXL_20210503_225117107 by Robert Stone, on Flickr

Discovered the distributor advance was set at only 5* with vacuum disconnected and plugged. I timed it for ~15* due to higher Boise elevation, but anywhere near the stock 12* put the nipple far too close to the power steering belt for comfort. Now I know why it was at only 5*!!:

PXL_20210503_232046930 by Robert Stone, on Flickr

PXL_20210503_232046930 by Robert Stone, on Flickr

Had to remove the dizzy after accounting for which cylinder the rotor was pointing at, then repositioned so I could get a better nipple location. More toward the power steering proved adequate for adjustment:

PXL_20210504_022731914 by Robert Stone, on Flickr

PXL_20210504_022731914 by Robert Stone, on Flickr

I reused the air cleaner assembly but will leave the vacuum hose off the end diaphragm since the flap inside closes when vacuum is applied, and that the fuel injection system doesn't need it.

EDITED THE FOLLOWING AFTER CONVERSATION LOWER IN THE THREAD:

The diaphragm closer to the air cleaner lid only opens when vacuum is connected, but since wide open throttle may cause it to close I decided to just wire it open permanently and leave the vacuum hose off it:

PXL_20210503_222746419 by Robert Stone, on Flickr

PXL_20210503_222746419 by Robert Stone, on Flickr

PXL_20210501_171632035 by Robert Stone, on Flickr

PXL_20210501_171632035 by Robert Stone, on FlickrTook forever to get the evap hoses out since I had to jack the passenger side up to get to the bolt that held the lines to the transmission. Once I got that bolt out I was able to wrangle the lines lower to remove the perma-clamps. Measured out new lengths, a bit longer to run them differently up the inner fender, and hose-clamped them to to the lines:

PXL_20210501_172147069 by Robert Stone, on Flickr

PXL_20210501_172147069 by Robert Stone, on FlickrTook forever to get the passenger side #4 cylinder air injection hole drilled out and retapped to screw in the new manifold plug, but it's done now:

PXL_20210430_020316927 by Robert Stone, on Flickr

PXL_20210430_020316927 by Robert Stone, on FlickrPart of the new fuel injection kit was getting a new O2 sensor hole drilled, bung welded up, and sensor screwed in. Local shop got that done for me. Was the first time I'd driven the beast on public roads more than a couple hundred feet. Placement was per Howell, in front of driver side pipe:

PXL_20210504_015137752 by Robert Stone, on Flickr

PXL_20210504_015137752 by Robert Stone, on FlickrAlso had the shop inspect the cat and as I figured it had been gutted and was useless, so had the shop weld up a new Magnaflow cat. Exhaust smells much better now!!:

PXL_20210503_222825088 by Robert Stone, on Flickr

PXL_20210503_222825088 by Robert Stone, on FlickrShop also removed the air injection pipe that went from driver side down to the original cat, with its custom water hose job. Unseen here was a large hole worn into the bottom of the pipe, making this thing useless even if everything else was good (which it wasn't!):

PXL_20210503_225117107 by Robert Stone, on Flickr

PXL_20210503_225117107 by Robert Stone, on FlickrDiscovered the distributor advance was set at only 5* with vacuum disconnected and plugged. I timed it for ~15* due to higher Boise elevation, but anywhere near the stock 12* put the nipple far too close to the power steering belt for comfort. Now I know why it was at only 5*!!:

PXL_20210503_232046930 by Robert Stone, on Flickr

PXL_20210503_232046930 by Robert Stone, on FlickrHad to remove the dizzy after accounting for which cylinder the rotor was pointing at, then repositioned so I could get a better nipple location. More toward the power steering proved adequate for adjustment:

PXL_20210504_022731914 by Robert Stone, on Flickr

PXL_20210504_022731914 by Robert Stone, on FlickrI reused the air cleaner assembly but will leave the vacuum hose off the end diaphragm since the flap inside closes when vacuum is applied, and that the fuel injection system doesn't need it.

EDITED THE FOLLOWING AFTER CONVERSATION LOWER IN THE THREAD:

The diaphragm closer to the air cleaner lid only opens when vacuum is connected, but since wide open throttle may cause it to close I decided to just wire it open permanently and leave the vacuum hose off it:

PXL_20210503_222746419 by Robert Stone, on Flickr

PXL_20210503_222746419 by Robert Stone, on Flickr

Comment