puttin' a carb together for a pal. thought someone may find it helpful if i showed my work.

4350 motorcraft off a FSJ.

first,remove the top cover screws. 10 of them. they are the larger phillips headed screws. i forgot to snap a pic of the float removal,but pretty simple.pull the pin.

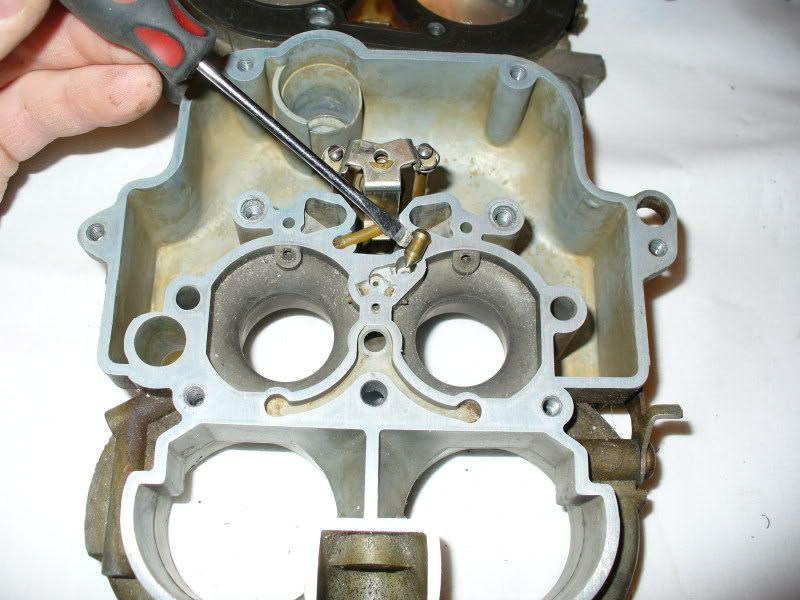

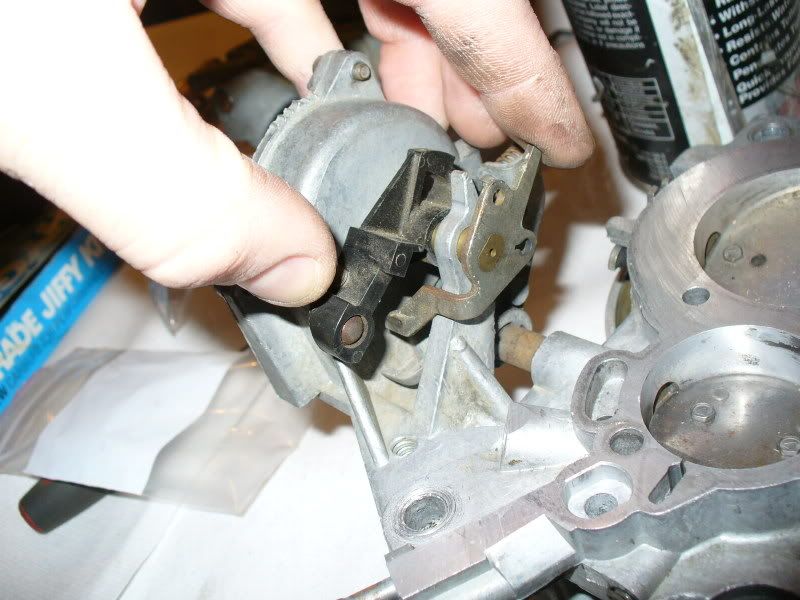

next,remove the clip from the accelerator pump link,at the throttle arm.

there is also a clip on the lower choke link,remove it,to remove the link from the lower arm.

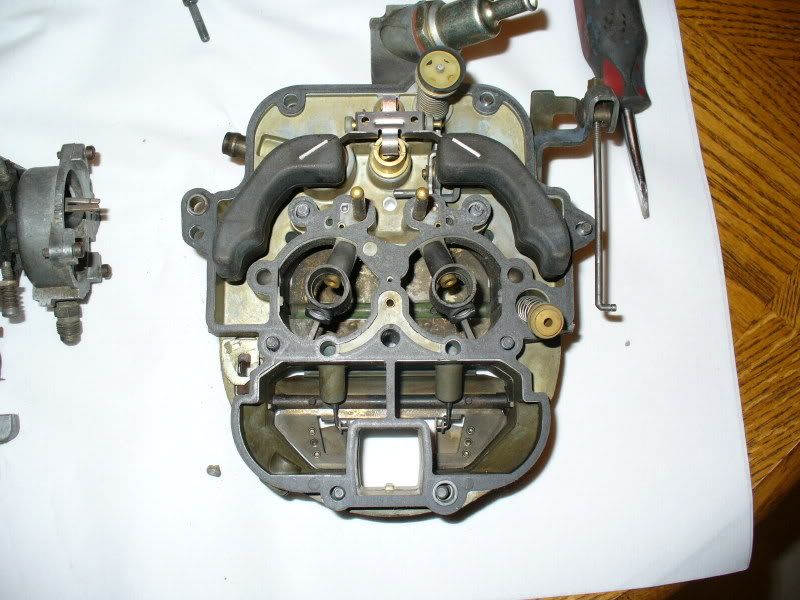

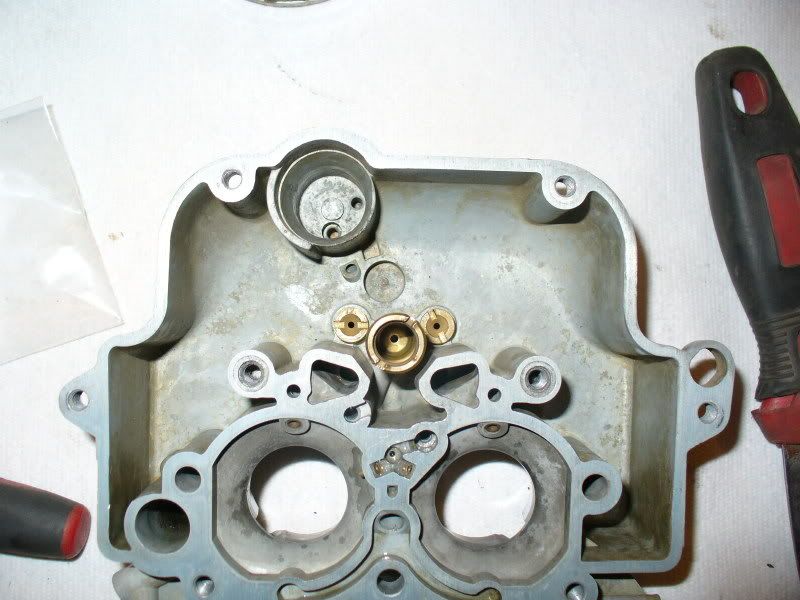

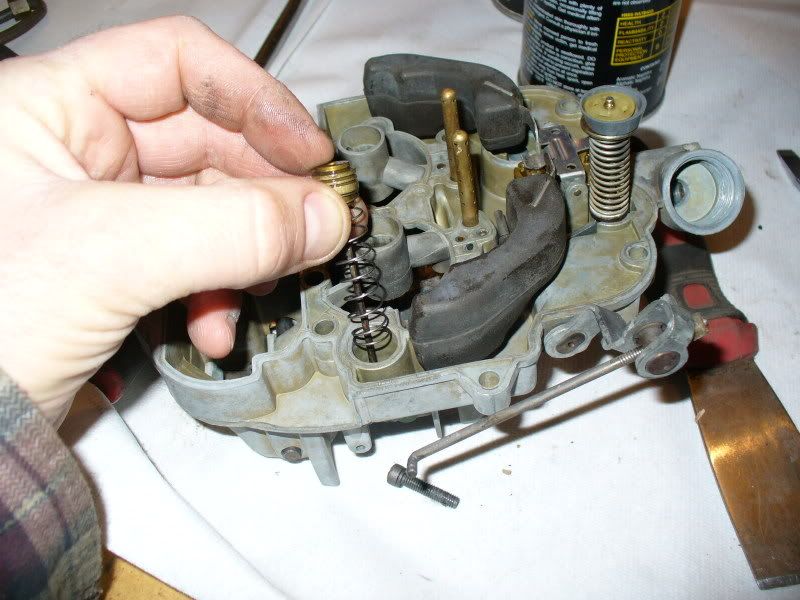

and the top will lift off. this is the underside-what's inside the carb.

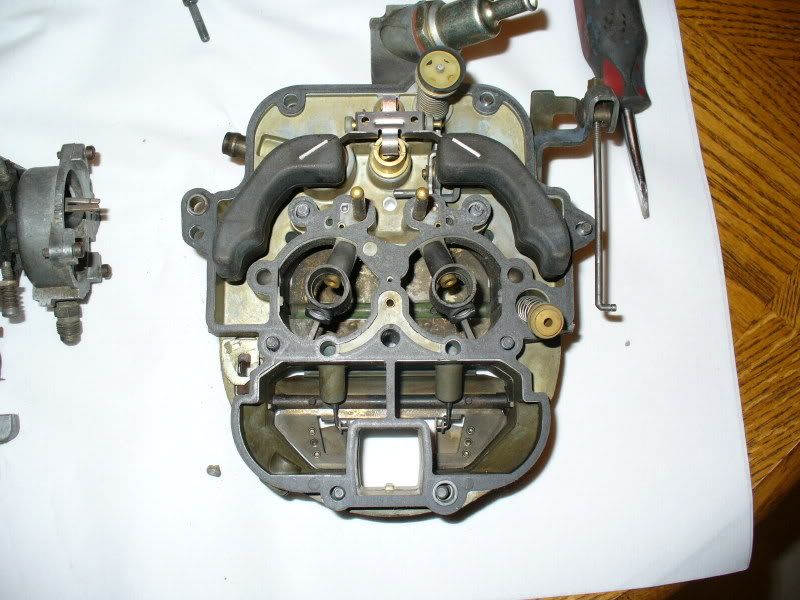

here is the main body with the top off.

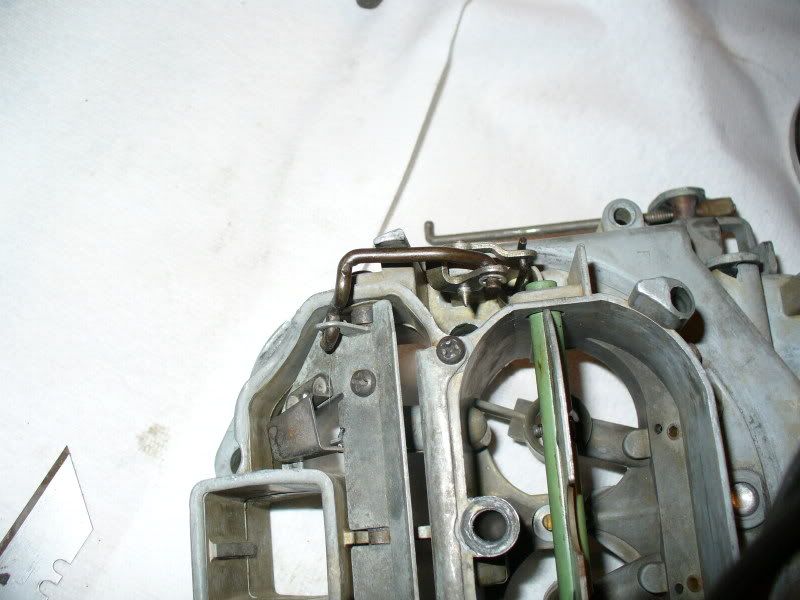

next,remove the 6 screws holding the throttle body to the bottom of the main body.

and separate them.

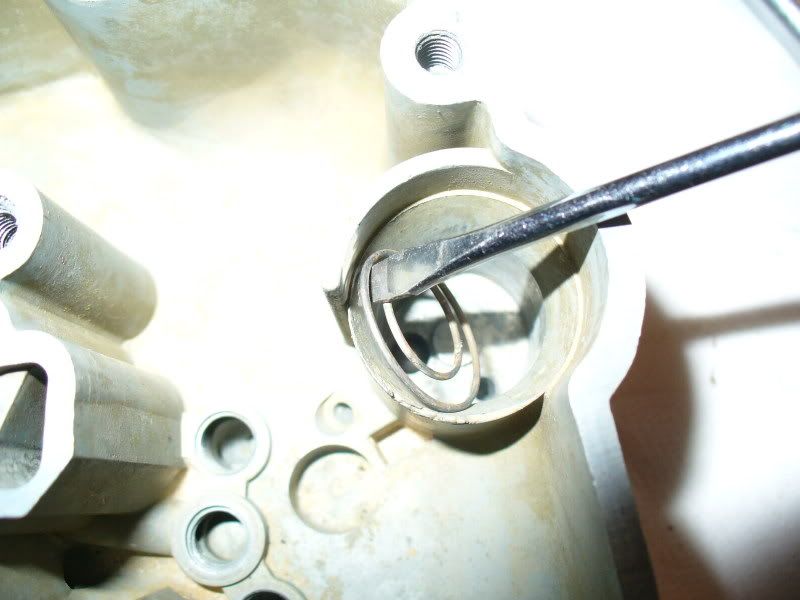

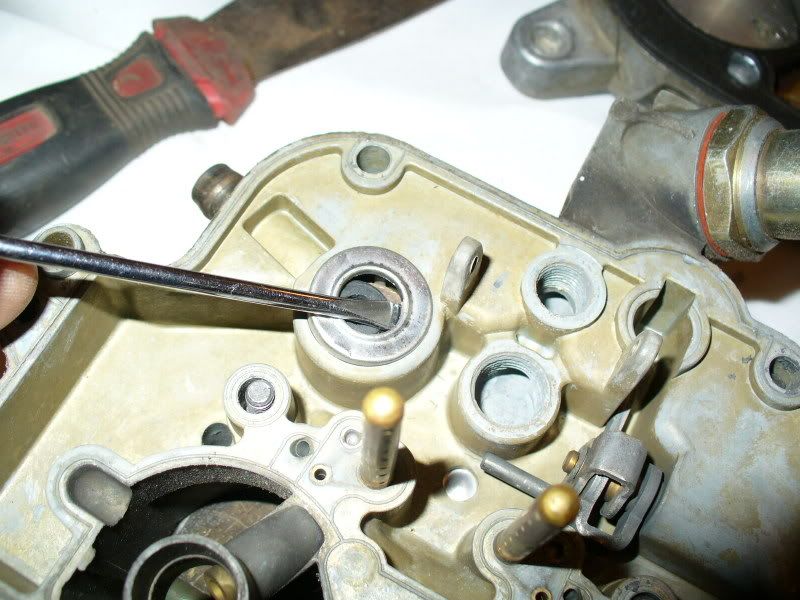

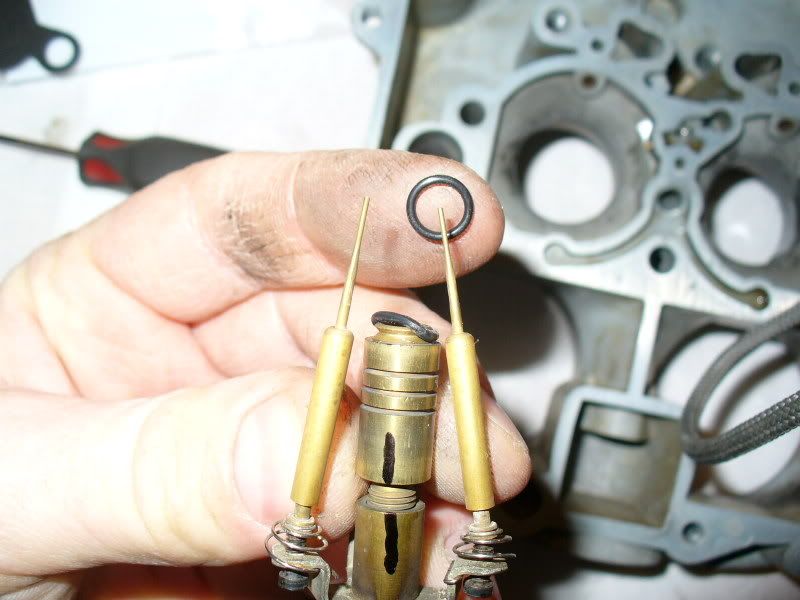

next,we'll move to internal dis-assembly.

4350 motorcraft off a FSJ.

first,remove the top cover screws. 10 of them. they are the larger phillips headed screws. i forgot to snap a pic of the float removal,but pretty simple.pull the pin.

next,remove the clip from the accelerator pump link,at the throttle arm.

there is also a clip on the lower choke link,remove it,to remove the link from the lower arm.

and the top will lift off. this is the underside-what's inside the carb.

here is the main body with the top off.

next,remove the 6 screws holding the throttle body to the bottom of the main body.

and separate them.

next,we'll move to internal dis-assembly.

Comment