Thanks for the great info, keep it comin'

)

) )

)

)

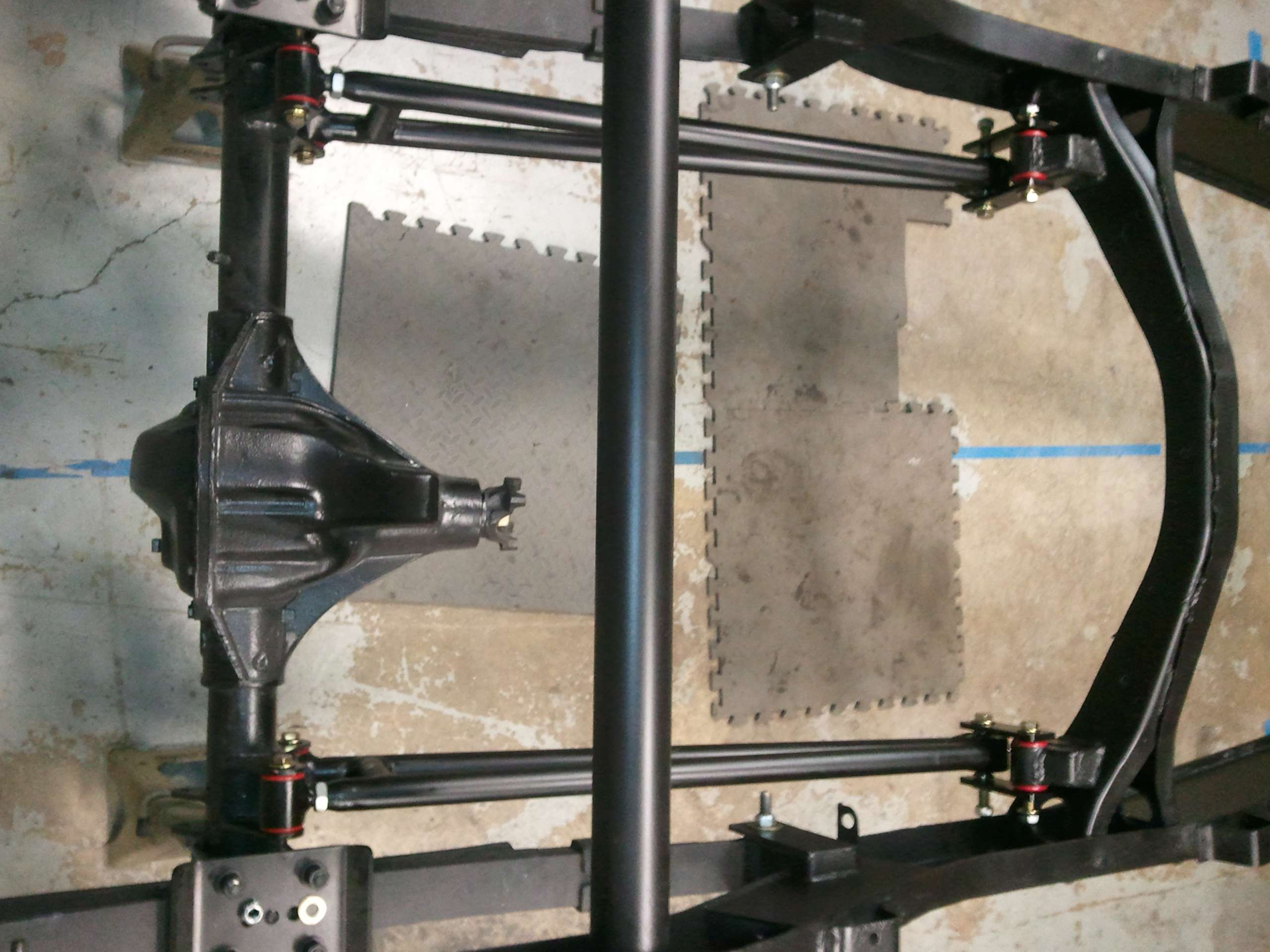

) Like I said earlier, I just retired. I want to build a tough, simple truck that will last longer than I do. I don't expect it to do any one thing great, but I do want it to handle most anything I ask of it relatively well.

Like I said earlier, I just retired. I want to build a tough, simple truck that will last longer than I do. I don't expect it to do any one thing great, but I do want it to handle most anything I ask of it relatively well.

Comment