I have a few 383's out there in AMC cars but now I finally get to build one for a Full Size Jeep!

To get to 383 cubic inches, it requires a 4.155" bore and 3.53" stroke

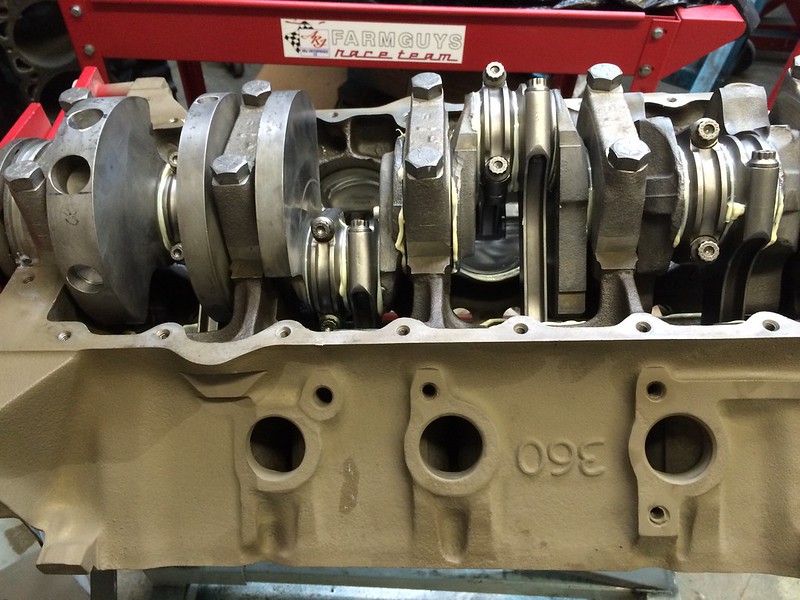

Here is the block all cleaned and ready to go.

IMG_4319 by Rick Jones, on Flickr

IMG_4319 by Rick Jones, on Flickr

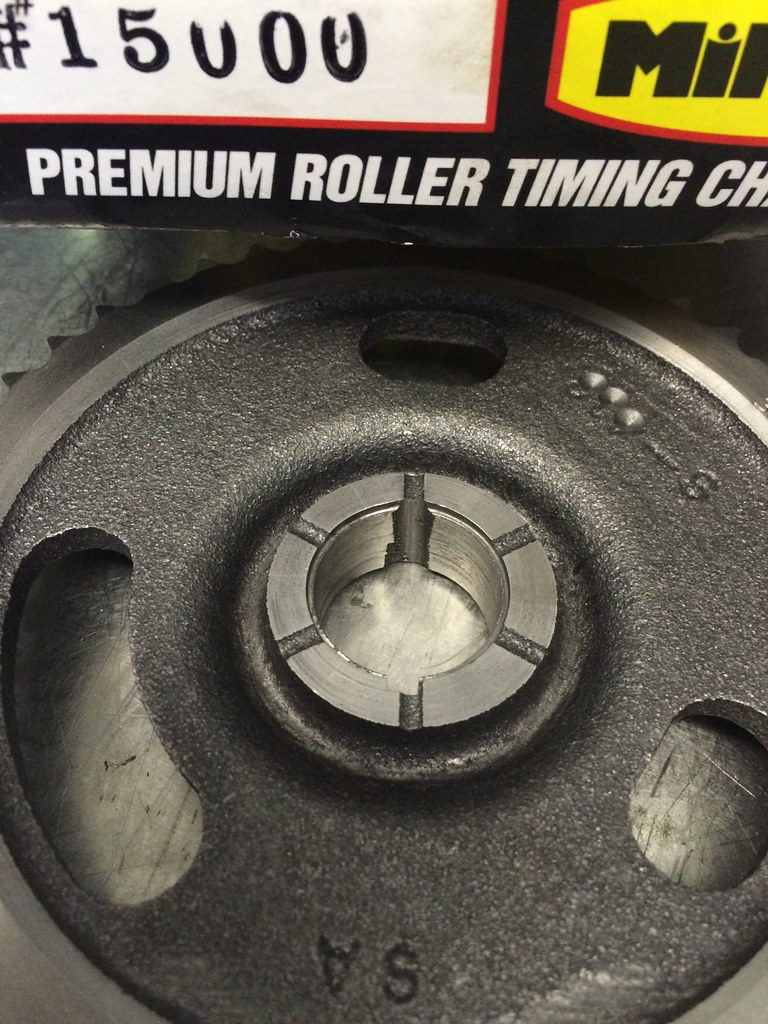

I love part numbers with "RD" or "X" in them. "RD" means Research and Development but a "X" could mean anything.

IMG_4315 by Rick Jones, on Flickr

IMG_4315 by Rick Jones, on Flickr

This block is a late Jeep block. The extra core plugs in the back were added to the drawing 2-5-1979

IMG_4316 by Rick Jones, on Flickr

IMG_4316 by Rick Jones, on Flickr

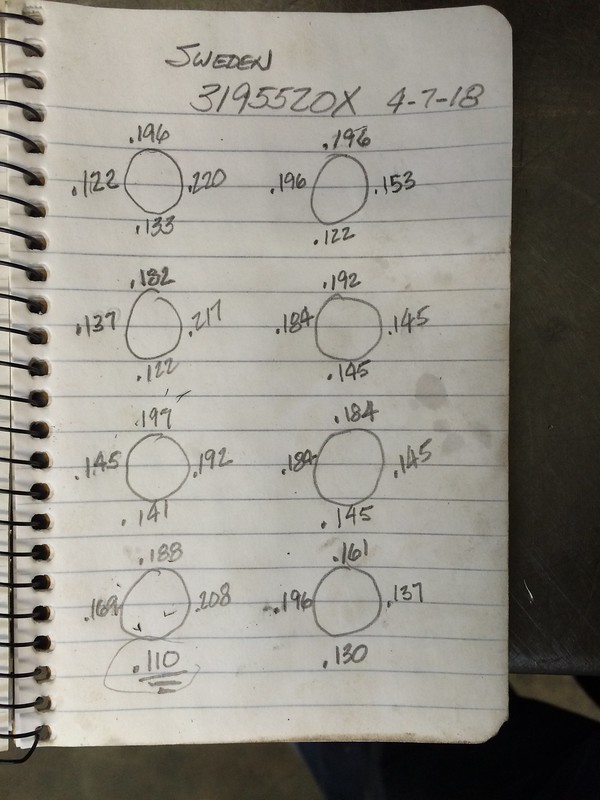

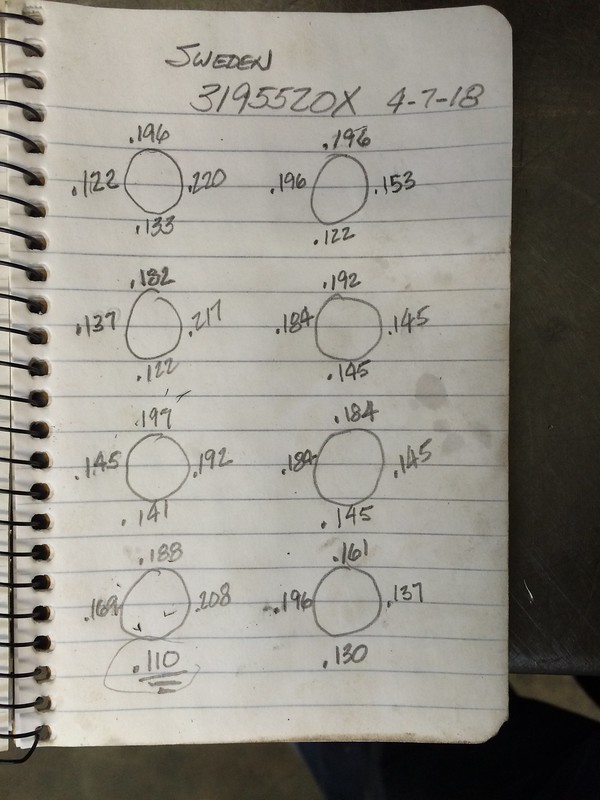

I Sonic check the block before and after boring. I check several places until I find the thinnist spots.

IMG_4318 by Rick Jones, on Flickr

IMG_4318 by Rick Jones, on Flickr

This is nice thick block. The absolute thinnist spot is .110". This block could have been bored out to the 401 bore of 4.165" and would have still been ok. I go to 4.155" because it is a standard size and to stay on the safe side.

IMG_4320 by Rick Jones, on Flickr

IMG_4320 by Rick Jones, on Flickr

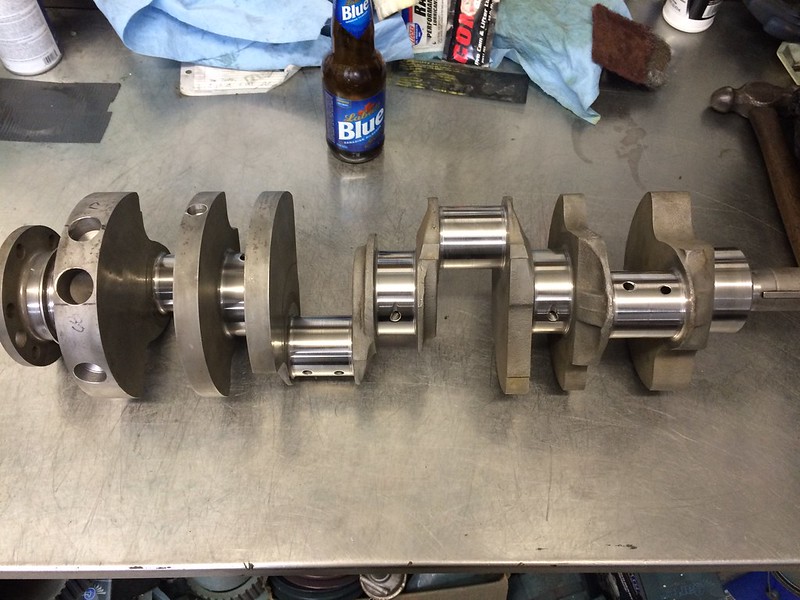

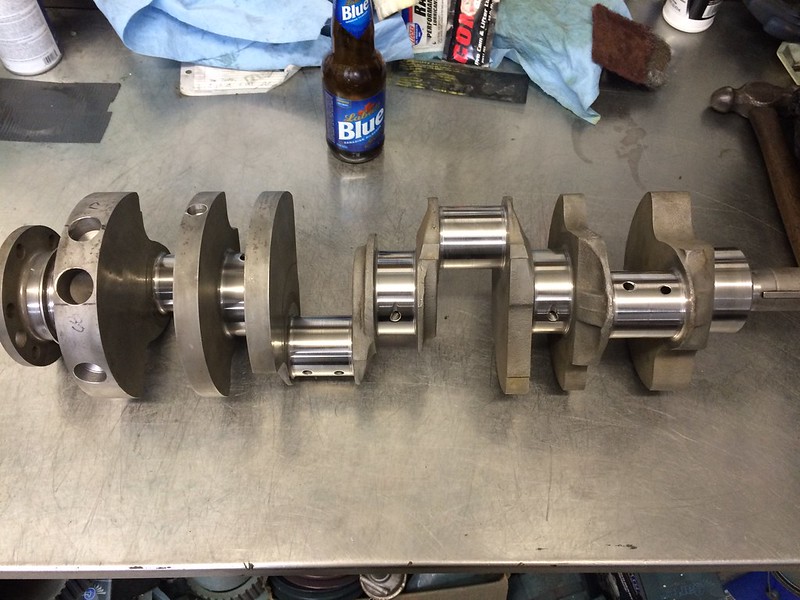

Here is the purdy crankshaft. I had it off-set ground to a 2" journal with a 3.53" stroke.

IMG_4321 by Rick Jones, on Flickr

IMG_4321 by Rick Jones, on Flickr

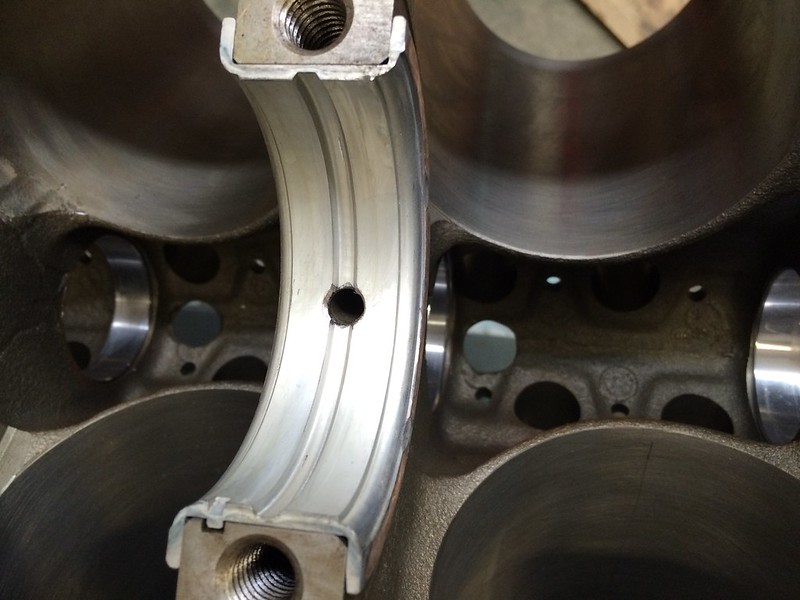

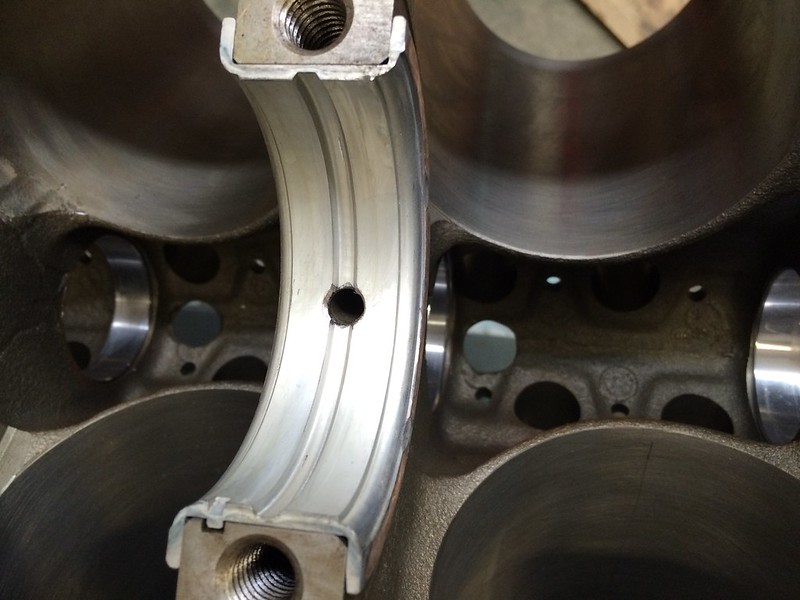

On the performance engines I drill out the main bearing feed holes to match the 5/16" oil feed hole below it.

IMG_4322 by Rick Jones, on Flickr

IMG_4322 by Rick Jones, on Flickr

To get to 383 cubic inches, it requires a 4.155" bore and 3.53" stroke

Here is the block all cleaned and ready to go.

IMG_4319 by Rick Jones, on Flickr

IMG_4319 by Rick Jones, on FlickrI love part numbers with "RD" or "X" in them. "RD" means Research and Development but a "X" could mean anything.

IMG_4315 by Rick Jones, on Flickr

IMG_4315 by Rick Jones, on FlickrThis block is a late Jeep block. The extra core plugs in the back were added to the drawing 2-5-1979

IMG_4316 by Rick Jones, on Flickr

IMG_4316 by Rick Jones, on FlickrI Sonic check the block before and after boring. I check several places until I find the thinnist spots.

IMG_4318 by Rick Jones, on Flickr

IMG_4318 by Rick Jones, on FlickrThis is nice thick block. The absolute thinnist spot is .110". This block could have been bored out to the 401 bore of 4.165" and would have still been ok. I go to 4.155" because it is a standard size and to stay on the safe side.

IMG_4320 by Rick Jones, on Flickr

IMG_4320 by Rick Jones, on FlickrHere is the purdy crankshaft. I had it off-set ground to a 2" journal with a 3.53" stroke.

IMG_4321 by Rick Jones, on Flickr

IMG_4321 by Rick Jones, on FlickrOn the performance engines I drill out the main bearing feed holes to match the 5/16" oil feed hole below it.

IMG_4322 by Rick Jones, on Flickr

IMG_4322 by Rick Jones, on Flickr

Comment