Thanks for all the pics and information. Great stuff to learn.

AMC360 Budget Build w/343 Pistons

Collapse

X

-

SC,

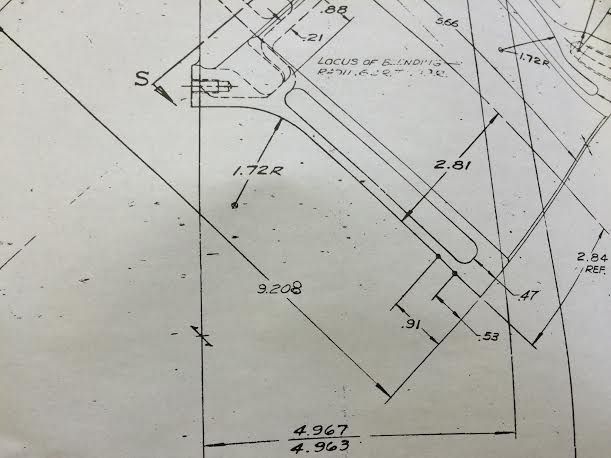

Just for my own curiosity, do those prints show the specified deck height? Sorry to be pedantic. I'm just curious whether the design specs reflect real life measurements.'85 J20 Old Man Truck, bought @ 65K miles - not great, but better than walking.

Member, FSJ Prissy Restoration Association

High quality junk here: intro thread and slow build thread

Did you know? Willys is just Willis spelled differently, but pronounced the same. Neither Willy nor his apostrophe are involved.

Comment

-

-

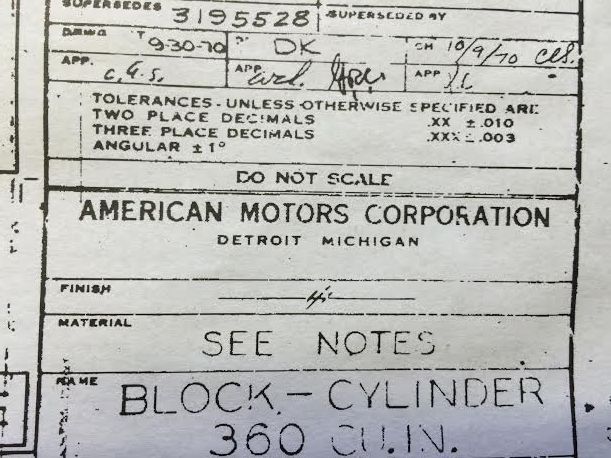

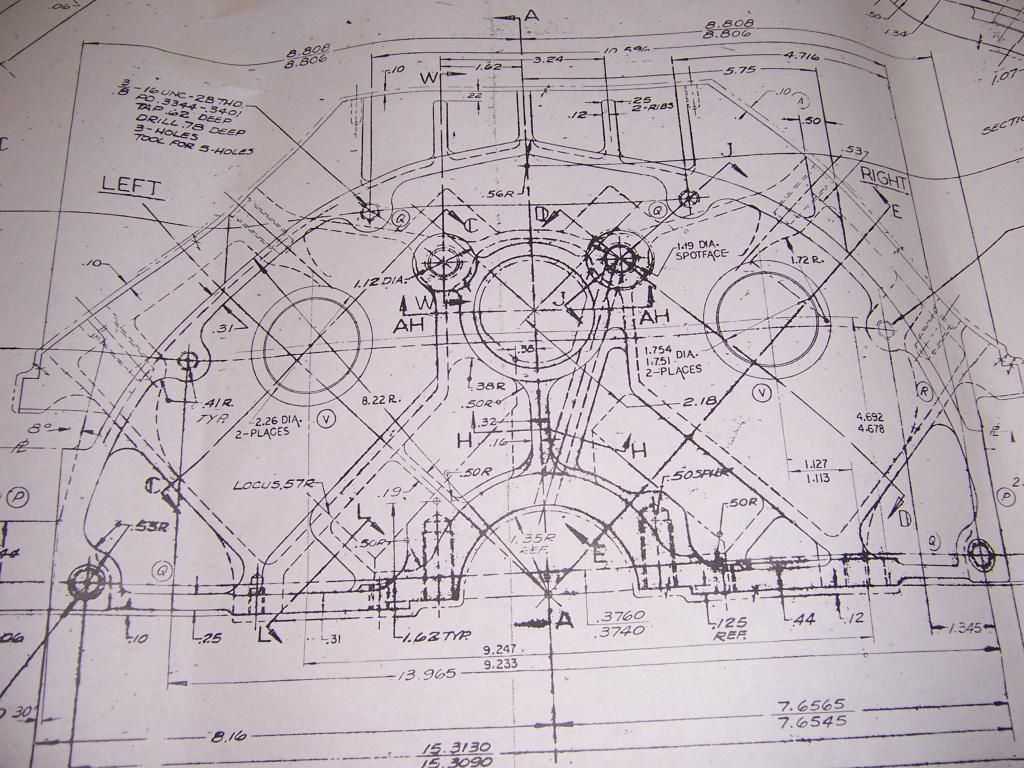

Well, let me find the dimension on the drawing first.....Originally posted by DarkMonohueSC,

Just for my own curiosity, do those prints show the specified deck height? Sorry to be pedantic. I'm just curious whether the design specs reflect real life measurements.

Here it is! 9.208"

Title block tolerance on that dimension is +- 0.003". Now, I just have to get my machinist to measure one..

The Squeaky Wheel gets replaced in my world

The Squeaky Wheel gets replaced in my world

Comment

-

-

I guess we will have to find another source. Here is one...Originally posted by rockosockoSC, I've 'googled' and Badger pistons seems to be defunk'd and gone.

Where can one get an oversize set if you know..

Thanks and great build, want more.

E

Last edited by SC/397; 04-03-2016, 03:50 PM.The Squeaky Wheel gets replaced in my world

Comment

-

-

Well, I have the block all cleaned up and cam bearings installed. Time to check the oil passages through the cam and on to the distributor gear. Summit cam and SA Gear timing gear via CarQuest. Check it out, not even close! If I would have installed it as is, the distributor gear would have failed very quickly.

I checked it out with a old stock timing gear and it was way off as well. Guess they drilled the hole in the cam in the wrong place. You have to check every part!

I did the normal thing and got the die grinder out and re-located the slot.

It lines up now..

On the front side, I braze the slots shut and clean out the oil passage with my trusty die grinder. The original factory timing gear doesn't have the slots.

I use white lith grease on the cam journals and put it in the block. It should spin by hand using the timing gear. This one spins nice. I put the cam lobe lube on as it is sitting in the block. It is just easier for me to do it that way.

The Squeaky Wheel gets replaced in my world

The Squeaky Wheel gets replaced in my world

Comment

-

-

Above and beyond. Thanks for doing that. There's so much bunk repeated around the internet that I couldn't pass up a chance to get the real number.Originally posted by SC/397Here it is! 9.208"

Title block tolerance on that dimension is +- 0.003". Now, I just have to get my machinist to measure one..'85 J20 Old Man Truck, bought @ 65K miles - not great, but better than walking.

Member, FSJ Prissy Restoration Association

High quality junk here: intro thread and slow build thread

Did you know? Willys is just Willis spelled differently, but pronounced the same. Neither Willy nor his apostrophe are involved.

Comment

-

-

Originally posted by SC/397I guess we will have to find another source. Here is one...

http://www.ebay.com/itm/AMC-Jeep-AMX...KQK2aw&vxp=mtr

Thank you Sir.

I thought of rebuilding the 360 from my J10, just to freshen it up, but you got me thinking of checking the cam timing pin hole and trying to measure how many degrees off of the broached keyway on the stock cam.

It's just sitting on the shop floor waiting.

When did they start using the plastic coated teeth on the cam gear?

Would you know if one can use those little advance/retard 'inserts' like a cheby?

I pulled up this to use as a pic of the back of a roller timing gear that Falcon sells. It's got the key way but no hole for the pin. BUT a gazillion keyways on the crank gear.

Comment

-

-

All of the '66 and up stock engines had nylon gear timing sets. They used nylon to reduce noise. The heavy duty, fleet and Police applications used steel gears.

The key ways are ok. It is the oil transfer slots that is the problem. I haven't seen any off-set keys for AMC but that doesn't mean that they don't make them or, they can't be made. I have never had a problem with degreeing the cams in with the multiple key-way slot like the Roll-Master. You don't need the off-sset keys for that one especially. Be carefull with the Roll-master. They must have changed machining methods and have screwed up the front side of them by adding huge leak passages (in thoughts of dispursing oil to the chain). I weld them all shut (except for the one at the key slot)

"It's got the key way but no hole for the pin" - I don't understand what you mean by "pin". There is no pin on a AMC timing set.

.... Just realized what you are asking me. On the cam side of Roll Master there is a 180 degree cavity for the oil to flow in to, around and through the slot to the distributor gear. It doesn't have the little notch like the rest of them do. I made up the little pin to help me figure out where the slot is suppose to be by sticking it in the cam oil hole..

Rollmaster is probably one of the best timing sets that you can buy but here we go again. They changed...

Rollmaster is probably one of the best timing sets that you can buy but here we go again. They changed...

Last edited by SC/397; 04-05-2016, 06:53 AM.The Squeaky Wheel gets replaced in my world

Last edited by SC/397; 04-05-2016, 06:53 AM.The Squeaky Wheel gets replaced in my world

Comment

-

-

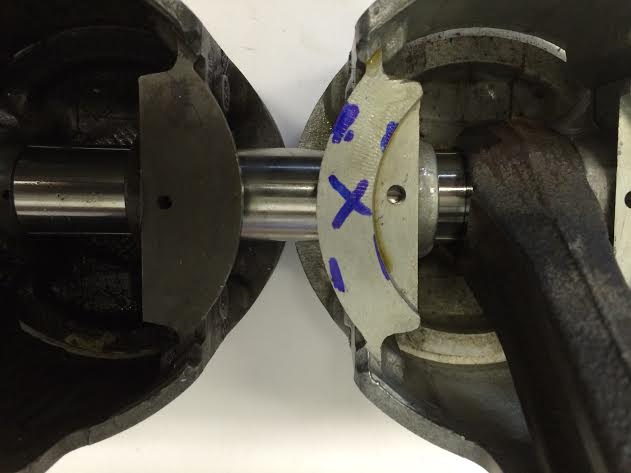

Here is a new one... Clevite bearings have been making bearings since Shep was a pup. I guess they got tired and forgot to put the locating tab in this one. I am sure that it is the only one that is out there... (yea, right)

I didn't feel like taking the time to send them back so, I did the best I could with it without screwing it up.

The Squeaky Wheel gets replaced in my world

The Squeaky Wheel gets replaced in my world

Comment

-

-

I knew that there was a reason that I didn't like Badger Pistons...

So, I installed the #1 piston in the block and went to spin the crank like I always do but, it was locked up. Wouldn't move and Immediatly knew why. The bottom of the piston at the pin hits the crank throw. I have had this problem before with Badger pistons on couple of stock 390 builds but forgot to check the Badger 343 pistons..

Glad they don't make the dam things any more!

Time to do some more homework. First thing I did was compair a factory stock 343 piston with the Badger piston and quickly found the problem. The Badger piston has 0.083" more material below the pin!

The Badger piston has a extra rib on the bottom side vs the stock piston.

Then I compaired a stock 343 piston vs a stock 360 piston. There is 0.030" difference but there would still have been enough clearance.

I compaired the Badger 343 piston to a replacement 360 piston and there was 0.055" difference.

And last, I measured a different brand 343 replacement piston and found it to be 0.075" shorter.

Conclusion: Don't use Badger pistons in the future.

The fix.. Either machine the pistons or crank throws. I elected to machine the crank throws and get the crank rebalanced...The Squeaky Wheel gets replaced in my world

Comment

-

-

So, you have to machine EVERY throw of the crank, or just a couple?

Just thinking that besides the 'novelty' of using the 343 pistons, it seems like it's more expensive to build up using the 343 pistons versus getting ZERO deck and milling cyl heads to raise compression.

It seems like then, it would be more of a 'trial' with push-rod lengths to the rockers. (or are the head thicknesses too thin to allow a milling to raise compression?)

I'm not downing your build by any way, It just seems that you would think that some company would've come out with a high compression piston for a amc 360. (Isn't there high compression pistons for the 401? And didn't they make MORE 360's?)

I wanted to build a higher compression Buick 4.1 a while back and a seller on Ebay 'made' some, but at the time wasn't cost effective and never pulled the trigger. Then when I did, they weren't offered..

Thanks again for the knowledge and pictures.

E

Comment

-

-

No problem!Originally posted by rockosockoSo, you have to machine EVERY throw of the crank, or just a couple?

I could have gotten away with just machining the tops of just the front and rear throw but, I did them all.

Just thinking that besides the 'novelty' of using the 343 pistons, it seems like it's more expensive to build up using the 343 pistons versus getting ZERO deck and milling cyl heads to raise compression.

It is not a novelty and It is not more expensive at all. I should have noted that a different brand 343 piston (other than the Badger) would have worked fine. I tried to show that in the pictures. The fact that Badger doesn't make pistons any more is a good thing. As far as milling down the block and heads - it would take way too much to get the same compression ratio. The piston change is a much better way and a bolt in.. with newer 343 pistons

It seems like then, it would be more of a 'trial' with push-rod lengths to the rockers. (or are the head thicknesses too thin to allow a milling to raise compression?)

You would have to machine too much off of both the heads and block to get close to the same compression ratio. The bigger issue would be having to machine the intake manifold to fit as well. Not worth it.

I'm not downing your build by any way, It just seems that you would think that some company would've come out with a high compression piston for a amc 360. (Isn't there high compression pistons for the 401? And didn't they make MORE 360's?)

They do.. it is called a 343 flat top piston or a forged piston

I wanted to build a higher compression Buick 4.1 a while back and a seller on Ebay 'made' some, but at the time wasn't cost effective and never pulled the trigger. Then when I did, they weren't offered..

Thanks again for the knowledge and pictures.

E

I was just pointing out that if I had done my homework a little better and used newer pistons there wouldn't have been a problem. Again, I have had this problem on a normal 390 build with Badger pistons.Last edited by SC/397; 04-06-2016, 09:40 AM.The Squeaky Wheel gets replaced in my world

Comment

-

Comment