In another thread I mentioned my gamble on the OMIX drums was not a winner. Not entirely junk, but if I have to do it again, I'd bet on a lower price table.

So here's the tale.

Oct - Nov 2013

Installed Raybestos D52 front brake pads (friction code FF)

Replaced front Parking brake cable,

On the rear brake backing plates brazed the contact points.

Installed Raybestos 462PG shoes (friction rating EE) with new hardware.

The front brakes really grabbed hard. Felt like too much initial bite.

Possibly I thought this may have been because the previous rear shoes had higher friction rating.

Sometimes on the highway and certain sideroads I'd notice a noise that I just didn't seem to have time to track down.

Fast forward to Nov 2017, roughly 13,500 miles later. Discovered the left rear parking brake cable had been stuck causing the lead shoe to drag.

Lots of fun to replace that. Not!

Rebrazed and filed the contact points, checking the hieghts the best I could with a dial indicator.

The old shoes were toast, and the drum scored up.

Plan A was to have the drums turned. But after looking at the rust holes coming through lip, I figured at best, the shop wasn't going to like doing 'em and probably wouldn't do 'em.

This time I wanted to make sure all of the parts were as correct as possible. One puzzle I wanted to solve was which shoe frame (aka web or backing plate) was the correct one. In my earlier investigations I had discovered that each of the previous shoes I had purchased used different frames. I found photos of original shoes for sale on e-bay.

I found photos of original shoes for sale on e-bay.

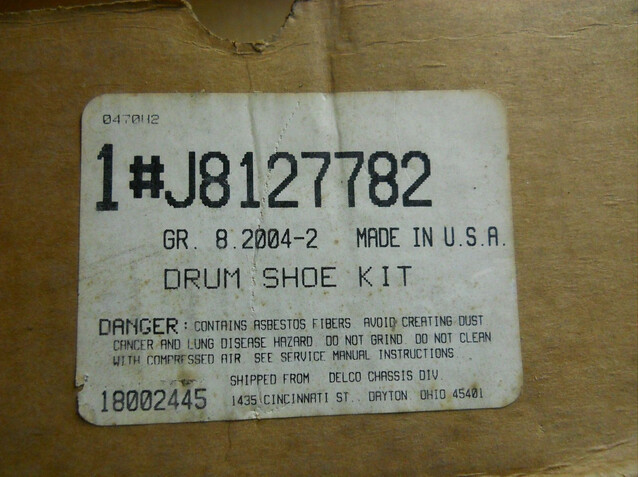

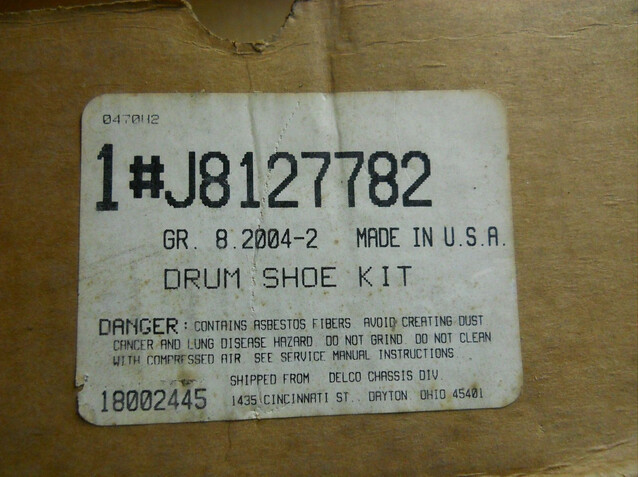

ebay-oe-shoes-edge-codes

ebay-oe-shoes-edge-codes

Looking at various replacements, only OMIX seemed to have the correct frame. So I bought them. They are correct frame. Don't know who made them for OMIX. Whomever did, does not participate in the Frictional Manufacture's use of edge codes. (Centrics didn't used to either, but if you wrote they would provide the friction rating. With new rules in some of the West Coast states, all shoes and pads will start to have edge codes)

Don't know who made them for OMIX. Whomever did, does not participate in the Frictional Manufacture's use of edge codes. (Centrics didn't used to either, but if you wrote they would provide the friction rating. With new rules in some of the West Coast states, all shoes and pads will start to have edge codes)

OMIX-462-Brake-shoes-6139

OMIX-462-Brake-shoes-6139

Anyway, based on the positive results of shoe frames being correct, I took a gamble on the OMIX drums. When they arrived it was pretty obvious that not only was it a low quality casting, but the machine and finish work are pretty subpar. Inside, which was hard to photograph, is machined OK. Outside, the weights, the welds, and the 'hand finishing' are just fugly.

OMIX-Brake-Drums-6149

OMIX-Brake-Drums-6149

OMIX-Brake-Drums-6158

OMIX-Brake-Drums-6158

So here's the tale.

Oct - Nov 2013

Installed Raybestos D52 front brake pads (friction code FF)

Replaced front Parking brake cable,

On the rear brake backing plates brazed the contact points.

Installed Raybestos 462PG shoes (friction rating EE) with new hardware.

The front brakes really grabbed hard. Felt like too much initial bite.

Possibly I thought this may have been because the previous rear shoes had higher friction rating.

Sometimes on the highway and certain sideroads I'd notice a noise that I just didn't seem to have time to track down.

Fast forward to Nov 2017, roughly 13,500 miles later. Discovered the left rear parking brake cable had been stuck causing the lead shoe to drag.

Lots of fun to replace that. Not!

Rebrazed and filed the contact points, checking the hieghts the best I could with a dial indicator.

The old shoes were toast, and the drum scored up.

Plan A was to have the drums turned. But after looking at the rust holes coming through lip, I figured at best, the shop wasn't going to like doing 'em and probably wouldn't do 'em.

This time I wanted to make sure all of the parts were as correct as possible. One puzzle I wanted to solve was which shoe frame (aka web or backing plate) was the correct one. In my earlier investigations I had discovered that each of the previous shoes I had purchased used different frames.

I found photos of original shoes for sale on e-bay.

I found photos of original shoes for sale on e-bay.

ebay-oe-shoes-edge-codes

ebay-oe-shoes-edge-codesLooking at various replacements, only OMIX seemed to have the correct frame. So I bought them. They are correct frame.

Don't know who made them for OMIX. Whomever did, does not participate in the Frictional Manufacture's use of edge codes. (Centrics didn't used to either, but if you wrote they would provide the friction rating. With new rules in some of the West Coast states, all shoes and pads will start to have edge codes)

Don't know who made them for OMIX. Whomever did, does not participate in the Frictional Manufacture's use of edge codes. (Centrics didn't used to either, but if you wrote they would provide the friction rating. With new rules in some of the West Coast states, all shoes and pads will start to have edge codes) OMIX-462-Brake-shoes-6139

OMIX-462-Brake-shoes-6139Anyway, based on the positive results of shoe frames being correct, I took a gamble on the OMIX drums. When they arrived it was pretty obvious that not only was it a low quality casting, but the machine and finish work are pretty subpar. Inside, which was hard to photograph, is machined OK. Outside, the weights, the welds, and the 'hand finishing' are just fugly.

OMIX-Brake-Drums-6149

OMIX-Brake-Drums-6149 OMIX-Brake-Drums-6158

OMIX-Brake-Drums-6158

Comment