Awesome writeup again sc. I read your other writeup on 401 crank in a 360 block but cannot see the pics. Dumb question time can you put stock 401 parts in a overbored 360 block and get a 401 or is the deck height lower on a 360 block?

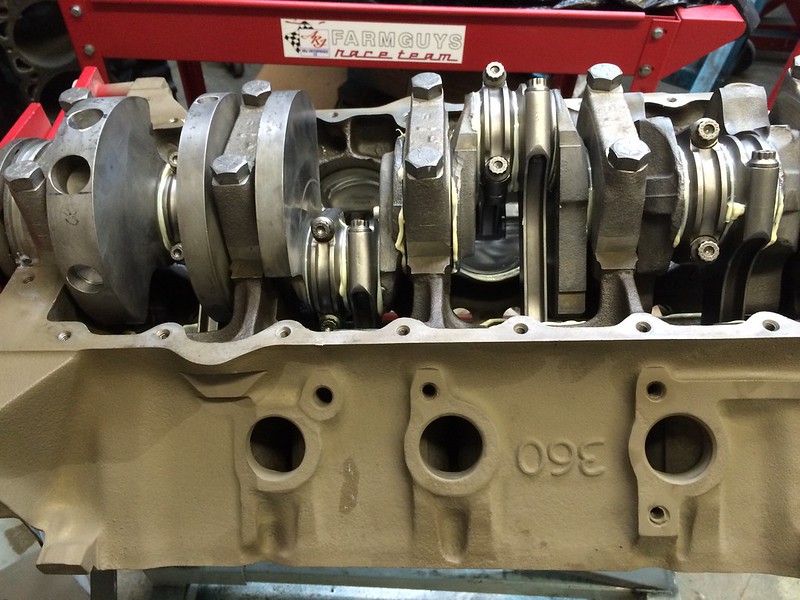

AMC 360 Stroker (383) for Donzi

Collapse

X

-

The deck height is the same on all the V8's after 1970 so, the 360 and 401 have the same deck height. The stroke is longer and the journals are bigger on the 401 crank so, you have to use the 401 rods. The pistons would be built to order to fit the 401 piston pin size, the bore size tat you specify, the pin height that you specfy, and the compression ratio that you specify.Originally posted by Gladiator4x4Awesome writeup again sc. I read your other writeup on 401 crank in a 360 block but cannot see the pics. Dumb question time can you put stock 401 parts in a overbored 360 block and get a 401 or is the deck height lower on a 360 block?

The short answer is yes you could put the 401 crank, rods and pistons in a 360 block but it would require a bore of 4.165". It has been done before.

- Not recommended unless you sonic check the block to make sure it can handle that big of bore.The Squeaky Wheel gets replaced in my world

Comment

-

-

Making a little more progress...

Bultear doesn't sell matching Distributor Gear sets any more so I will be trying a pair from MSD.

camgear by Rick Jones, on Flickr

camgear by Rick Jones, on Flickr

I chase all of the threads in the entire engine with a tap. This takes a little time but has saved me headaches in the long run. It still amazes me how much crud gets jambed in the tapped holes. This is the timing cover. I would have never gotten a bolt in these two holes without cleaning them out first. Alot of it is old RTV.

tap1 by Rick Jones, on Flickr

tap1 by Rick Jones, on Flickr

tap2 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

tap2 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

Comment

-

-

I love the detail in these writeups SC - keep'em coming & thanks for doing it!1984 GW

360

Comp 260H

Harland Sharp Roller Rockers

Wiseco -21cc Forged Pistons

Performer Intake

Holley SA 670

MSD 8523

Dakota Digital custom cluster

Serehill headlamp harness

NWMP aux tank

1987 GW deceased

...but the parts live on

Comment

-

-

msd gears are (were?) made by the same company that made the OEM,i was told by randy at PAS years ago.Originally posted by HankrodRistows right.................again,

Originally posted by Fasts79Chief... like the little 'you know what's' that you are.

Originally posted by Fasts79ChiefI LOVE how Ristow has stolen my comment about him ... "Quoted" it ... and made himself famous for being an ***hole to people. Hahahahahahahahahha!

It's like you're unraveling a big cable-knit sweater that someone keeps knitting...and knitting...and knitting...and knitting...

Comment

-

-

MSD is the way to go. I have installed 2 sets myself.Flint

Ran when parked.

http://jubileejeeps.org/quadratrac

88 GW, 401/727/208, 5" lift, D44s/4.10s/locked up, 35s with a few Evil Twin & TT's Fabworks mods

76 401 Wag, 77 401 Wag, 77 401 J20

http://eviltwinfab.com http://www.ttsfabworks.com

Comment

-

-

It's possible. They don't look like OEM gears to me but, my eyes are getting old...Originally posted by Ristowmsd gears are (were?) made by the same company that made the OEM,i was told by randy at PAS years ago.The Squeaky Wheel gets replaced in my world

Comment

-

-

For what it's worth, I had MSD gears in the first 401 I built way back in 2007 and they worked just fine. Keep up the good work Rick!Yep, I know my PM box is full. Email me instead.

1983 Cherokee WT - IFS, trailing arm rear, full cage, Hemi, 6 speed, turbocharged - Autocross project

http://ifsja.org/forums/vb/showthread.php?t=127321

Comment

-

-

Progress: I round up all of the right size bolts for the water pump and timing cover before I get everything all RTV'd up. I coat both sides of the gasket and install the water pump to the cover first with the bolts just snug - not tightened all the way.

IMG_4623 by Rick Jones, on Flickr

IMG_4623 by Rick Jones, on Flickr

Then I coat the side of the gasket that faces the block first then stick it to the block taking careful care by cleaning out any RTV that is in the oil passages..

IMG_4624 by Rick Jones, on Flickr

IMG_4624 by Rick Jones, on Flickr

Then I coat the back side of the timing cover again cleaning any RTV out of the oil passages.

IMG_4625 by Rick Jones, on Flickr

IMG_4625 by Rick Jones, on Flickr

I torque the timing cover bolts about 2/3 tight and then trim the excess gasket material at the block. The nextday I final torque all of the bolts.

IMG_4626 by Rick Jones, on Flickr

Last edited by SC/397; 06-04-2018, 06:35 PM.The Squeaky Wheel gets replaced in my world

IMG_4626 by Rick Jones, on Flickr

Last edited by SC/397; 06-04-2018, 06:35 PM.The Squeaky Wheel gets replaced in my world

Comment

-

-

What coating is that on the block? I assume it's a primer...?Originally posted by SC/397 Chuck McTruck 71 J4000

Chuck McTruck 71 J4000

(Chuck McTruck Build Thread)

(8.1L swap questions - PerformanceTrucks.net Forums)

79 Cherokee Chief (SOLD, goodbye old buddy)

(Cherokee Build Thread)

11 Nissan Pathfinder Silver Edition 4x4

09 Mazdaspeed3 Grand Touring

00 Baby Cherokee

Comment

-

-

It is Zinc Chromate Primer that I get at NAPA.

Here is a photo of the oil pick-up screen. I use a 1/4-20 x 3/8" long bolt and nut and Loctite them together to use as a button.

IMG_0115 by Rick Jones, on Flickr

IMG_0115 by Rick Jones, on Flickr

I make sure that the oil pick-up screen is located in the right position and test fit the oil pan without a gasket. If it fits without a gasket there are no problems.

IMG_0113 by Rick Jones, on Flickr

Last edited by SC/397; 07-15-2018, 02:03 PM.The Squeaky Wheel gets replaced in my world

IMG_0113 by Rick Jones, on Flickr

Last edited by SC/397; 07-15-2018, 02:03 PM.The Squeaky Wheel gets replaced in my world

Comment

-

-

I hope you use good protection equipment when using that!Originally posted by SC/397It is Zinc Chromate Primer that I get at NAPA.

Zinc chromate is some NASTY stuff, aerosol particles get all over place.

Hope you don?t have a dog or kids that could get exposed to particles.

I still believe that all the crap my dad was exposed to as an airline mechanic killed him courtesy of lung cancer. Zinc chromate is used a lot on planes.

He?s not the only mechanic to retire and then die from cancer.

I know of 2 others he was close friends with.

I also went to school for auto body and got extensive training on hazards of paints/chemicals. Some things are deadly, and gotta protect yourself(properly) from them. I always cringe when I see guys spraying w/o respirator or wearing just a dust mask.

Anyway rant over, awesone engine build as usual.Tony

88 GW, 67 J3000, 07 Magnum SRT8

Comment

-

-

Now that I am retired, maybe I can get caught up on engine building.

Block all together, got his fancy brass core plugs in full display, and now ready for the push rods, rocker arms and intake.

IMG_0039 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

IMG_0039 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

Comment

-

-

Progress: SCP 1097 BL- I have use quite a few sets of these Scorpion roller rocker arms. These are a direct replacement for the bridged rocker system.

IMG_0043 by Rick Jones, on Flickr

IMG_0043 by Rick Jones, on Flickr

To get the correct lifter pre-load (.040" +-.010" in this case) you can either shim the rocker pedestals or install the correct length push rods. Normally with these rocker arms I use a push rod that is somewhere between 8.200" to 8.300". In this case it fell right in the middle at 8.250".

IMG_0044 by Rick Jones, on Flickr

IMG_0044 by Rick Jones, on Flickr

Priming the oil pump.

IMG_0045 by Rick Jones, on Flickr

IMG_0045 by Rick Jones, on Flickr

I rotate the crank in about 1/4 increments and run the pump. I make sure that all the lifters are pumped up and that all the rocker arms get oil.

IMG_0046 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

IMG_0046 by Rick Jones, on Flickr

The Squeaky Wheel gets replaced in my world

Comment

-

Comment