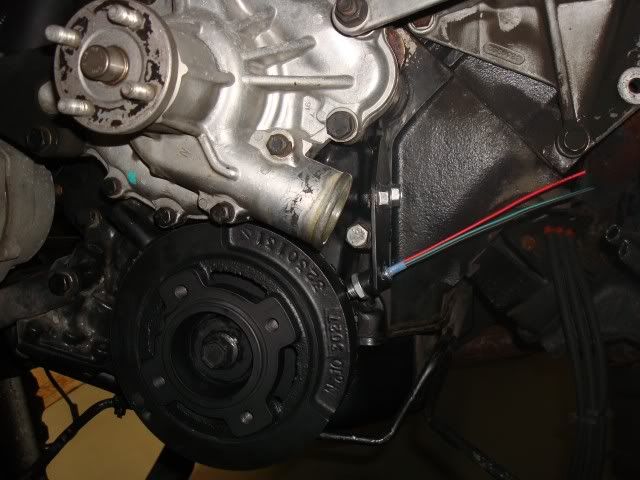

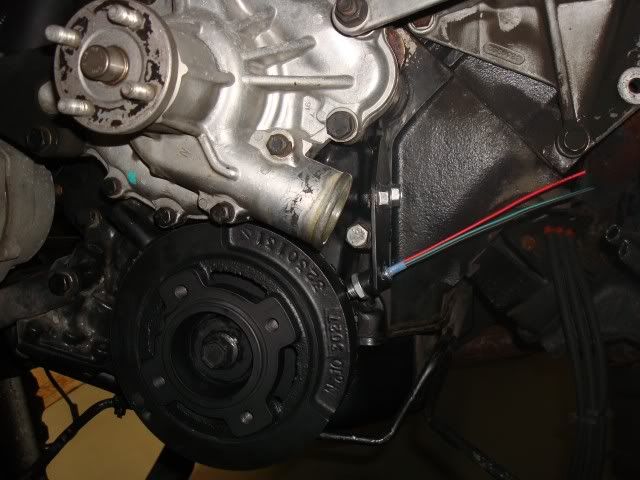

Here are the pictures of the completed toothed wheel install and the bracket to mount the gear tooth hall sensor. I fabbed up the sensor from an Allegro 616 and potted it into a threaded stud with a locknut, the bracket also serves as the fuel pump blockoff plate, I just extended it a few inches and welded a threaded bung to it at the proper angle for the wheel.

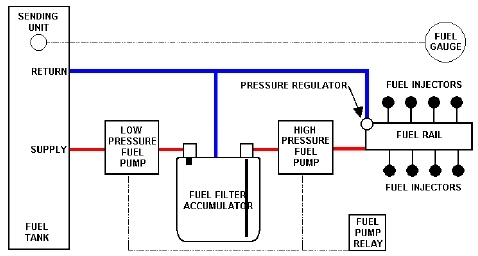

Next up is the gas tank....

Mike

Next up is the gas tank....

Mike

Comment