two things I forgot to add, if you switch to the silicon bronze wire you can't use a welding spoon with that wire because it will weld dissimilar metals, and the film is most likely from the acid dip so watch the fumes.

1970 J2500

Collapse

X

-

Do a test with some fine grit sandpaper and your wire brush. If they weld the same, it's your base material. If cleaning with a solvent doesn't help as much as you think it should, then try a fresh wire brush. If the brush isn't stiff enough, you are polishing the mill scale or "smearing" in any surface junk. Solvent first, then wire brusk/ sand paper clean.

Or..... did you mean the your welder was acting up and not running a smooth bead?Last edited by Funkatollah; 02-13-2017, 05:41 PM.

Comment

-

-

Appreciate the input. I tried .024 wire and .035. Strange as it may seem the 35 works better--beside I ran out of the 24Originally posted by toddthewelderUse acetone to clean the weld after you brush or grind on it. What size wire are you running in your machine? If you have the right size slots in the rollers of your machine you could try running a thinner wire and that would reduce the heat needed to weld, another thing to try is silicon bronze wire, it has a much lower melting point than the ER70s that you are running now. The pros of running the silicon bronze are that it is softer, so it grinds easier, lower melting point, pretty bronze color. the down side is that it isn't cheap, it looks like poo if you've never used it in a mig gun, and you have to shield it with 100%argon rather than the 75/25 that you are running now. Something else to keep in mind is that you just want to tack the metal and then move to another spot so things can cool (I'm more than sure you already knew that). It don't have to look good since you're grinding most of it back off. If none of those things work go to harbor freight and get a $10 welding spoon and hold it to the back of thin areas or places with a bad fit or big gap.

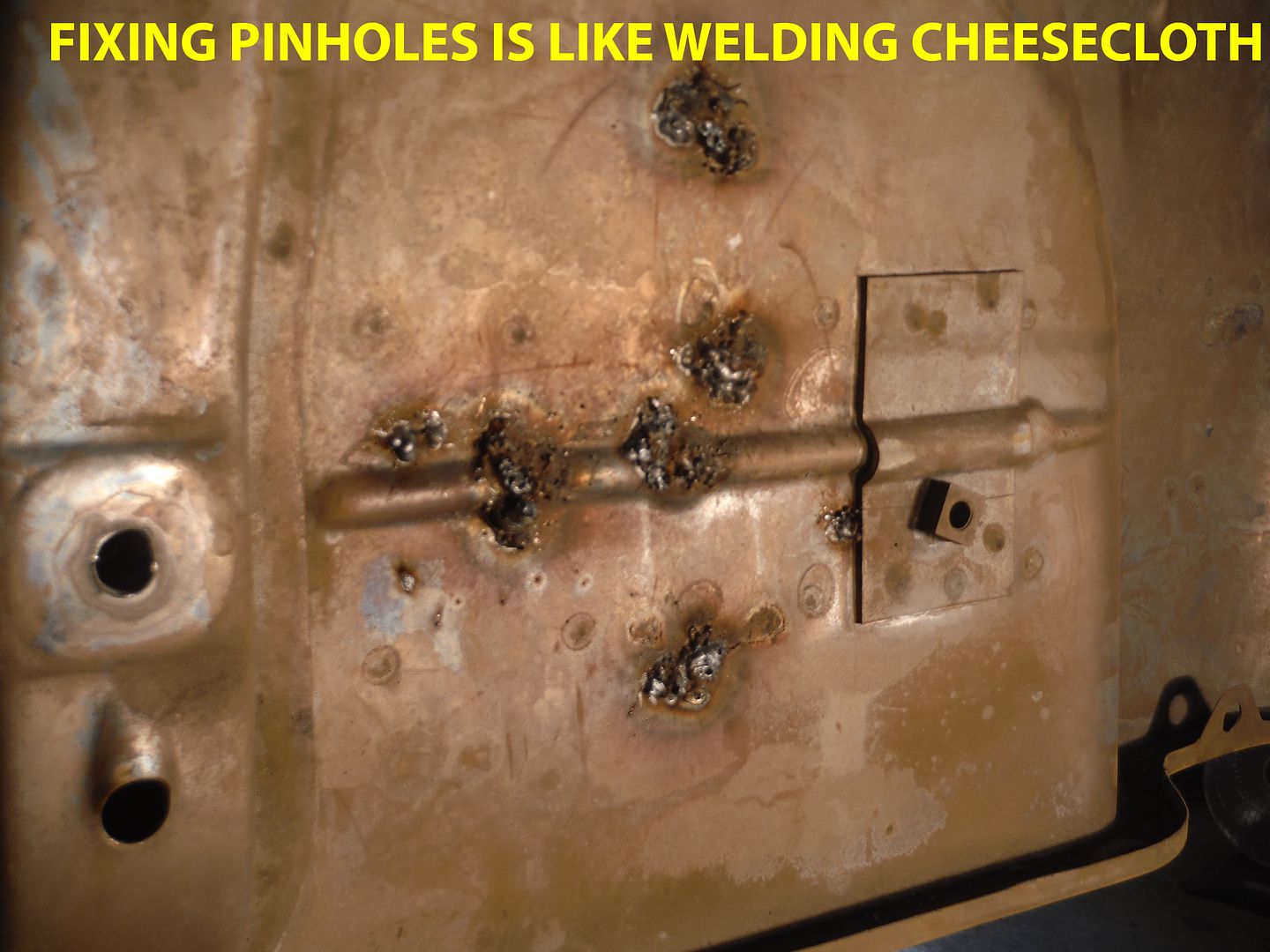

Hope some of that helps The real issue is when I hit those really thin areas caused by rust. Getting good at fixing holes.

The real issue is when I hit those really thin areas caused by rust. Getting good at fixing holes.

I have a dedicated stainless steel wire hand brush that I use. Seems to help that I scrubbed it with that brush after using the wire wheel.

I am too cheap to use the bronze although I have a bottle of Argon for aluminum I have had that same bottle for about 25 years so it tells you how much I weld aluminum . Its just easier to bemoan about it. Bemoan is short for

. Its just easier to bemoan about it. Bemoan is short for

and moan.

and moan.

I am headed to HF tomorrow for flapper disk and other expendables. Maybe a bending brake! also .

.

I hate this anticuss filter. when I say

I mean

I mean

.

Last edited by Frank Ziebert; 02-14-2017, 05:47 AM.1970 J2000(2500) Currently undergoing frame off resto

.

Last edited by Frank Ziebert; 02-14-2017, 05:47 AM.1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

Appreciate it. I actually have been welding to quite a while but never have run into this problem before. Those wire wheels were fresh out of the package.Originally posted by FunkatollahDo a test with some fine grit sandpaper and your wire brush. If they weld the same, it's your base material. If cleaning with a solvent doesn't help as much as you think it should, then try a fresh wire brush. If the brush isn't stiff enough, you are polishing the mill scale or "smearing" in any surface junk. Solvent first, then wire brush/ sand paper clean. 1970 J2000(2500) Currently undergoing frame off resto

1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

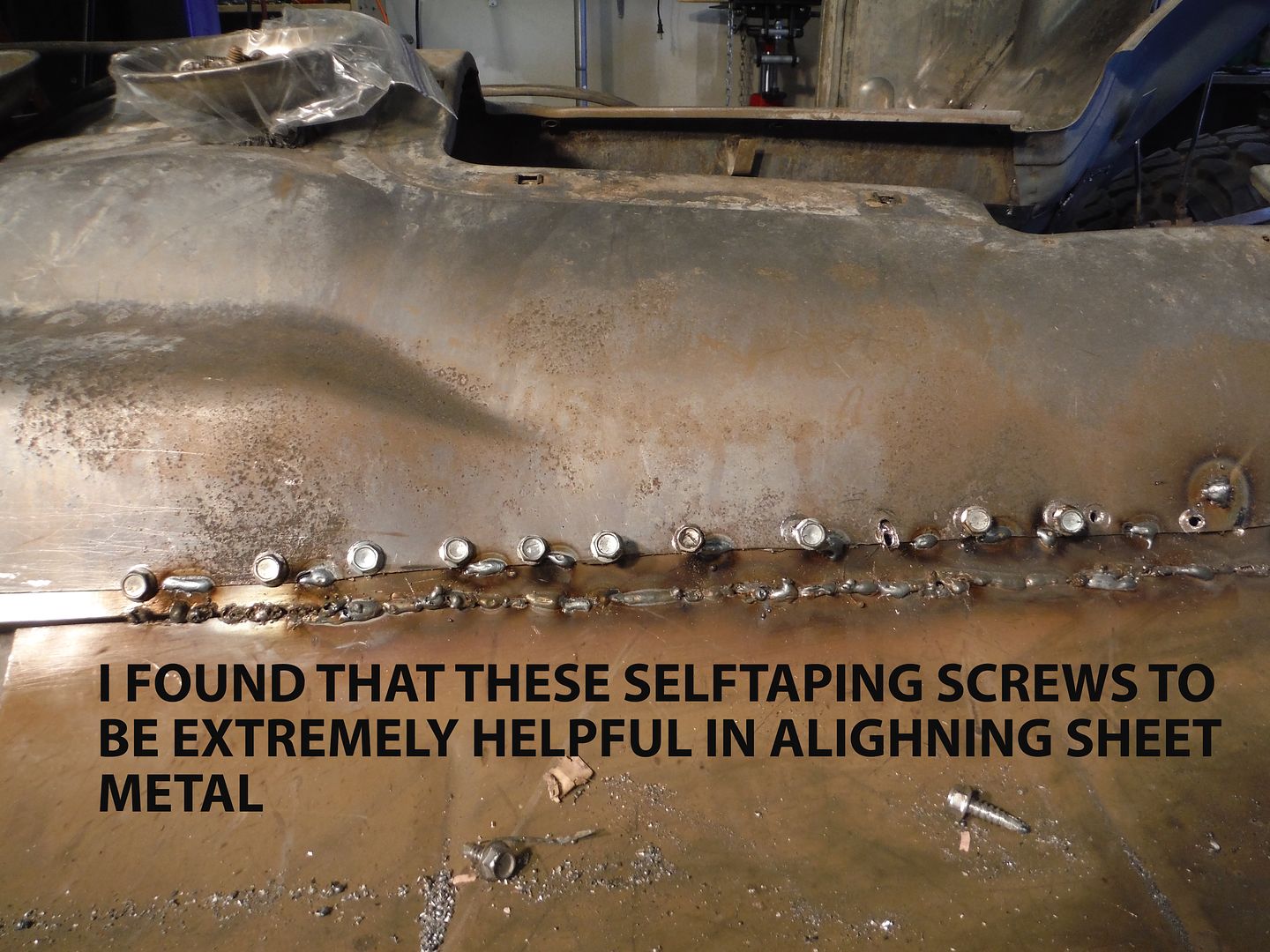

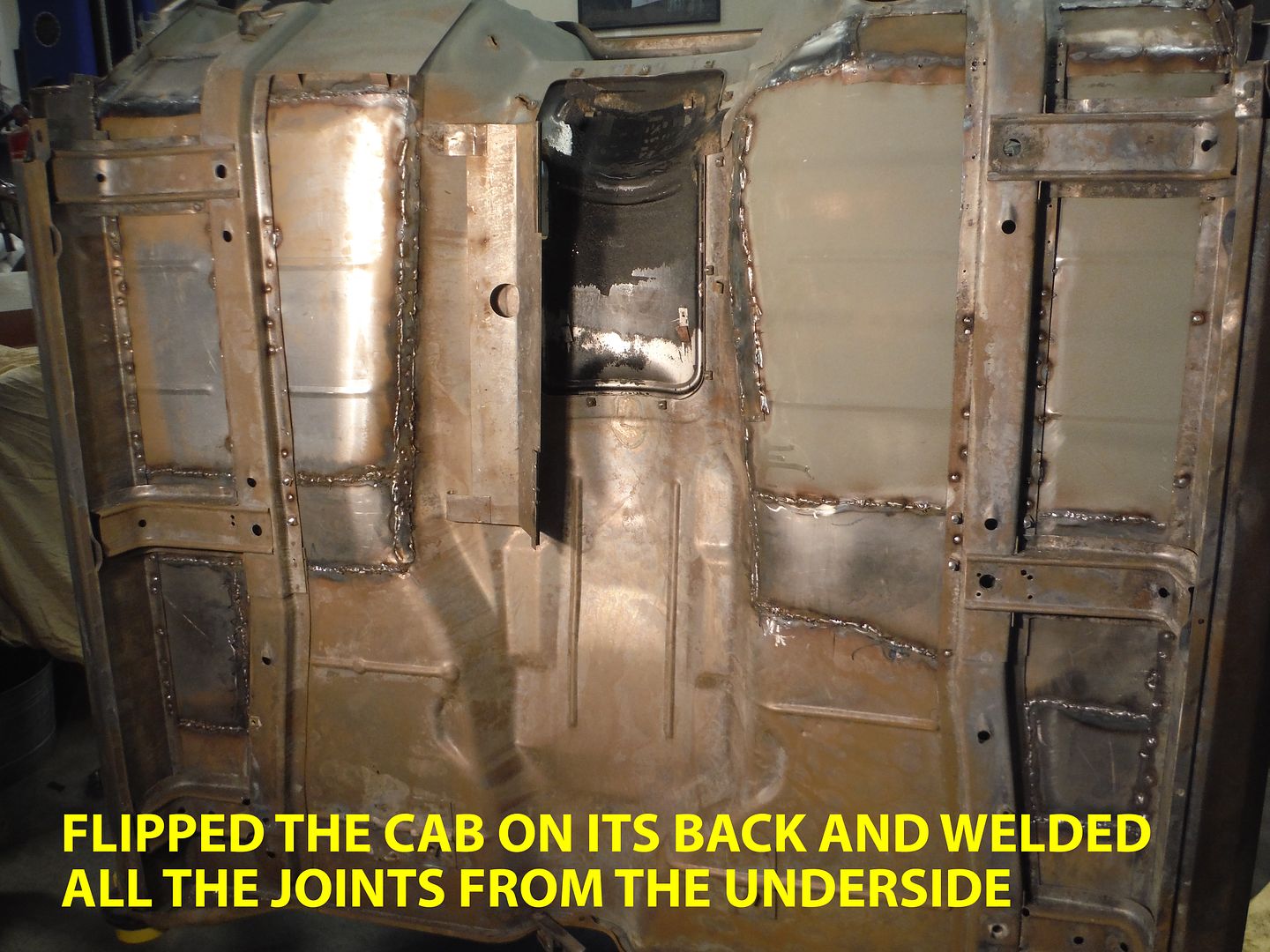

Making slow progress but still its progress. Fighting apparent contamination in the welding. Cant seem to trace it to the wire, the parent metal or the patch panels. cleaning the crap out of everything seems to help a bit. almost done with the floor on the drivers side. Trying to figure out the best approach in patching the areas of multiple rust pin holes in the roof. It is on enough of an angle trying to make a patch it a bear!

1970 J2000(2500) Currently undergoing frame off resto

1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

Painfully familiar sight! Looks like you're a little better at it than me though! That truck is going to be GREAT when you're done!'63 J200 Resto-mod in progress

(http://www.ifsja.org/forums/vb/showthread.php?t=178651)

If all goes well, we can toast to accidental successes.

I'm convinced I'm just too dumb to know that I can't restore this old truck...

Comment

-

-

Thanks. Sure hope it will have the looks to justify the effortOriginally posted by 63J200atLSUPainfully familiar sight! Looks like you're a little better at it than me though! That truck is going to be GREAT when you're done! 1970 J2000(2500) Currently undergoing frame off resto

1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

You are moving right along there. It looks like you used the same floor pan I bought. I found that the floor mounted gas pedal was canted at a terrible angle with no mods to the floor pan. I pounded the heck out of the corner to bring it flat and then smoothed it out with finish work. I used a sandbag and various plastic domed hammers and the shrinker stretcher to dial it in. If you find the same situation, just hang the pedal on the firewall.Originally posted by Frank ZiebertThanks. Sure hope it will have the looks to justify the effort

Looking great!Melford1972 says...

I’d say I feel sorry for you, but I really don’t, Mr. “I-stumble-into-X-models-the-way-most-people-stumble-into-Toyota-Carollas.” 🤣

-----------------------

I make wag parts

1969 CJ-5 41 years owned

1969 1414X Wag in avocado mist

1970 1414X Wag in avocado mist

1968 M715 restomod

2001 Dodge 3500

2002 Toyota Tundra

2006 Toyota 4runner was Liz's, parked

Building a m715 over at the m715zone

Beloved wife Elizabeth Ann Temple Murdered by covid on Oct 19th 2021

Small violin, large amp

Comment

-

-

Originally posted by KaiserjeepsYou are moving right along there. It looks like you used the same floor pan I bought. I found that the floor mounted gas pedal was canted at a terrible angle with no mods to the floor pan. I pounded the heck out of the corner to bring it flat and then smoothed it out with finish work. I used a sandbag and various plastic domed hammers and the shrinker stretcher to dial it in. If you find the same situation, just hang the pedal on the firewall.

Looking great!

I have already been looking for alternatives. Especially after seeing what you went through to get a stud mount working! 1970 J2000(2500) Currently undergoing frame off resto

1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

Did you solve the king pin bearing preload problem? I was replacing some shims today and found a PERFECT fit. Dana 60 preload shims are a dead ringer.

Like it was made for it.

I have 2 .018 shims and I have 2 .020 shims. If you still need them PM me your address and I will send 2 of the size of your choice to you. I suggest you put them on the top bearing. Less load there. Being thick they should hold up well. Probably the .018's would work best. They are the ones on the green paper. Time to sort that pile and hang them on pegboard.

I don't have enough shims....

Melford1972 says...

Melford1972 says...

I’d say I feel sorry for you, but I really don’t, Mr. “I-stumble-into-X-models-the-way-most-people-stumble-into-Toyota-Carollas.” 🤣

-----------------------

I make wag parts

1969 CJ-5 41 years owned

1969 1414X Wag in avocado mist

1970 1414X Wag in avocado mist

1968 M715 restomod

2001 Dodge 3500

2002 Toyota Tundra

2006 Toyota 4runner was Liz's, parked

Building a m715 over at the m715zone

Beloved wife Elizabeth Ann Temple Murdered by covid on Oct 19th 2021

Small violin, large amp

Comment

-

-

I haven't had time to go back to the chassis for anything yet. Still plugging holes in the cab. I have several sections of the roof about 6x6" or so that look like a shotgun target. Many pin holes but the section has compound angles and I am really hesitant to go cutting entire pieces out.

I'll pm on the shims. Thanks!1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

-

I was hoping to see a picture of that one. Cool beans. Those panel clamps are great. They establish the perfect gap when welding up. If the edges are touching it will cause issues and possible oil canning. If you get a spot that needs shrinking, try a shrinking disc on that peanut grinder. You have to take the paint off first. But the shrinking disc is very controllable. I like that tool a whole bunch.

Looking great Frank! Melford1972 says...

Melford1972 says...

I’d say I feel sorry for you, but I really don’t, Mr. “I-stumble-into-X-models-the-way-most-people-stumble-into-Toyota-Carollas.” 🤣

-----------------------

I make wag parts

1969 CJ-5 41 years owned

1969 1414X Wag in avocado mist

1970 1414X Wag in avocado mist

1968 M715 restomod

2001 Dodge 3500

2002 Toyota Tundra

2006 Toyota 4runner was Liz's, parked

Building a m715 over at the m715zone

Beloved wife Elizabeth Ann Temple Murdered by covid on Oct 19th 2021

Small violin, large amp

Comment

-

-

Originally posted by KaiserjeepsI was hoping to see a picture of that one. Cool beans. Those panel clamps are great. They establish the perfect gap when welding up. If the edges are touching it will cause issues and possible oil canning. If you get a spot that needs shrinking, try a shrinking disc on that peanut grinder. You have to take the paint off first. But the shrinking disc is very controllable. I like that tool a whole bunch.

Looking great Frank!

Thanks Al. I have some warping in the pan but it is not enough T cause me stress. The clamps made it so much easier. Wish I had used the from the start!!

Think I am going to try to graft the lid skin from the donor onto the project. The cancer is just too much to try to fix.1970 J2000(2500) Currently undergoing frame off resto

Stinger 2005 Jeep Unlimited, Sahara, Rubicon slightly modified

Comment

-

Comment