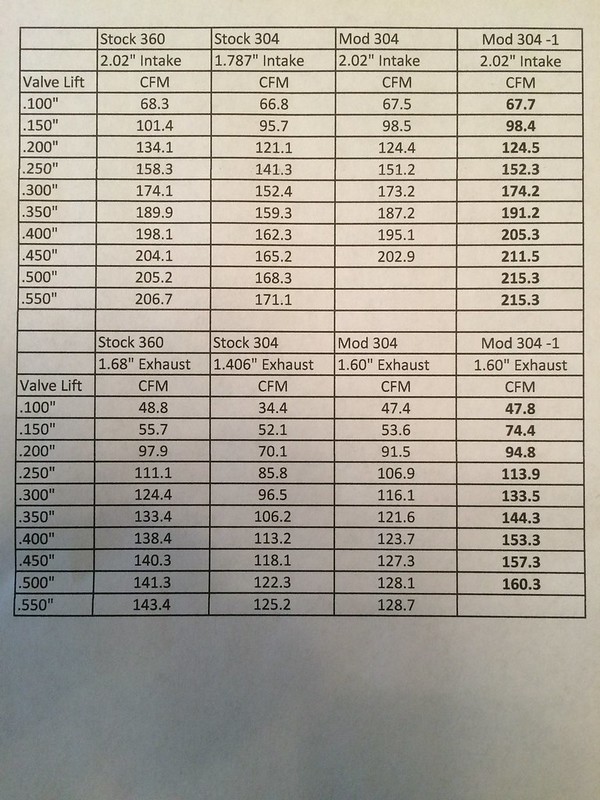

With the number of cracked 360/401 cylinder heads that I have been finding lately, I thought I would try to use 304 heads with bigger valves in them for the full size Jeep 360's that I build.

The idea is to use the chevy 2.02" / 1.60" valves in the 304 cylinder heads and hope that we can get the flow numbers to come close to a stock 360/401 head.

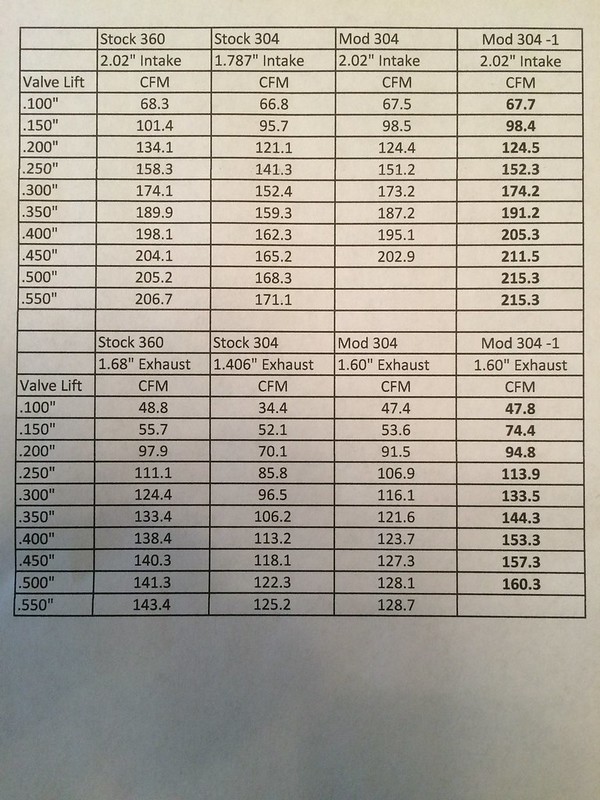

The first thing that I wanted to do was to just have them machined in and then measure the differences in flow between a stock 360 head, a stock 304 head and a modified 304 head with 2.02"/1.60" vlaves.

To do this we had to install new guides which have to be replaced about half the time anyway.

Our results for the stock 304 head is really close to what Mr. Parkman has recorded here so, I know that my numbers are fairly accurate. users.erols.com/srweiss/tablehdc.htm#AMC

The 360/401 cylinder head is a 1977 #3231475-1 and the 304 head is a 1978 #3233324-2.

I am really happy with the intake side. The exhaust side is not as close but is getting there. This is with no fancy work or anything. It is just what the cutter can do under normal machining.

I didn't want to have to do any more than that but to get the Exhaust flow numbers up I guess that I will have to.

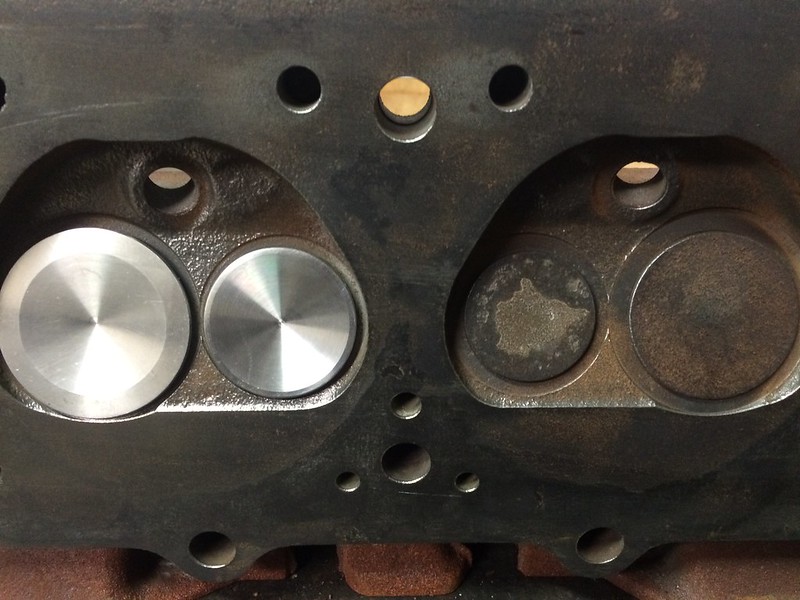

304 head 2.02"/1.60" left side, 1.787"/1.406" right side

IMG_2828 by Rick Jones, on Flickr

IMG_2828 by Rick Jones, on Flickr

IMG_2836 by Rick Jones, on Flickr

IMG_2836 by Rick Jones, on Flickr

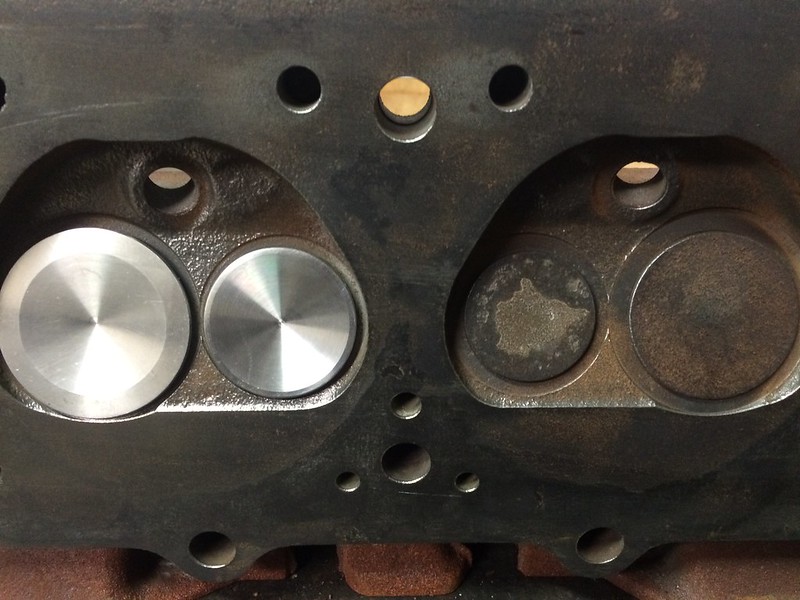

304 head machined for 2.02"/1.60" valves

IMG_2822 by Rick Jones, on Flickr

IMG_2822 by Rick Jones, on Flickr

IMG_2823 by Rick Jones, on Flickr

IMG_2823 by Rick Jones, on Flickr

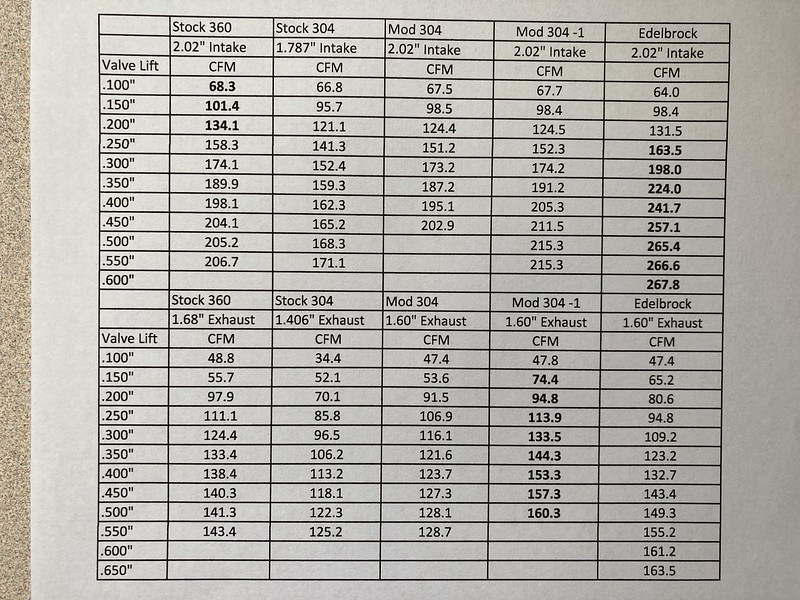

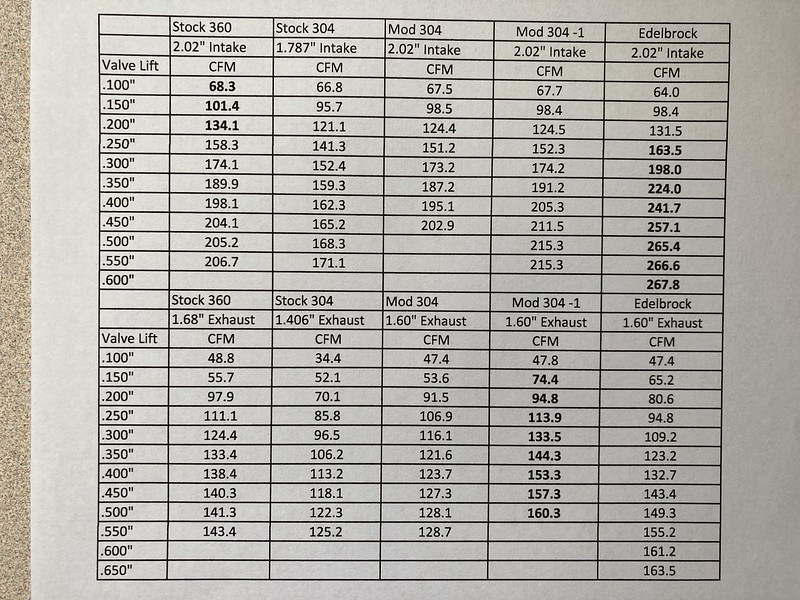

Chuck at the Machine Shop spent 45 minutes on each head blending in the short side radius. Looks to me that it was worth the effort.

This basically exceeds my hope of matching the flow of a stock 360 head with minimal work.

IMG_3102 by Rick Jones, on Flickr

IMG_3102 by Rick Jones, on Flickr

Here are the flow numbers from the Edelbrock Performer 401 heads. I port matched these a little better than delivered to match the intake gasket as well as match a header gasket.

I actually removed a fair amount of material at the Dog-Leg.

CylHdFloW by Rick Jones, on Flickr

CylHdFloW by Rick Jones, on Flickr

Interesting that the Edelbrocks pretty much equal the stock 360/401 head but are not hugely better as far as flow goes. Of course the bonus is no cracks and lighter weight.

The idea is to use the chevy 2.02" / 1.60" valves in the 304 cylinder heads and hope that we can get the flow numbers to come close to a stock 360/401 head.

The first thing that I wanted to do was to just have them machined in and then measure the differences in flow between a stock 360 head, a stock 304 head and a modified 304 head with 2.02"/1.60" vlaves.

To do this we had to install new guides which have to be replaced about half the time anyway.

Our results for the stock 304 head is really close to what Mr. Parkman has recorded here so, I know that my numbers are fairly accurate. users.erols.com/srweiss/tablehdc.htm#AMC

The 360/401 cylinder head is a 1977 #3231475-1 and the 304 head is a 1978 #3233324-2.

I am really happy with the intake side. The exhaust side is not as close but is getting there. This is with no fancy work or anything. It is just what the cutter can do under normal machining.

I didn't want to have to do any more than that but to get the Exhaust flow numbers up I guess that I will have to.

304 head 2.02"/1.60" left side, 1.787"/1.406" right side

IMG_2828 by Rick Jones, on Flickr

IMG_2828 by Rick Jones, on Flickr IMG_2836 by Rick Jones, on Flickr

IMG_2836 by Rick Jones, on Flickr304 head machined for 2.02"/1.60" valves

IMG_2822 by Rick Jones, on Flickr

IMG_2822 by Rick Jones, on Flickr IMG_2823 by Rick Jones, on Flickr

IMG_2823 by Rick Jones, on FlickrChuck at the Machine Shop spent 45 minutes on each head blending in the short side radius. Looks to me that it was worth the effort.

This basically exceeds my hope of matching the flow of a stock 360 head with minimal work.

IMG_3102 by Rick Jones, on Flickr

IMG_3102 by Rick Jones, on FlickrHere are the flow numbers from the Edelbrock Performer 401 heads. I port matched these a little better than delivered to match the intake gasket as well as match a header gasket.

I actually removed a fair amount of material at the Dog-Leg.

CylHdFloW by Rick Jones, on Flickr

CylHdFloW by Rick Jones, on FlickrInteresting that the Edelbrocks pretty much equal the stock 360/401 head but are not hugely better as far as flow goes. Of course the bonus is no cracks and lighter weight.

Comment