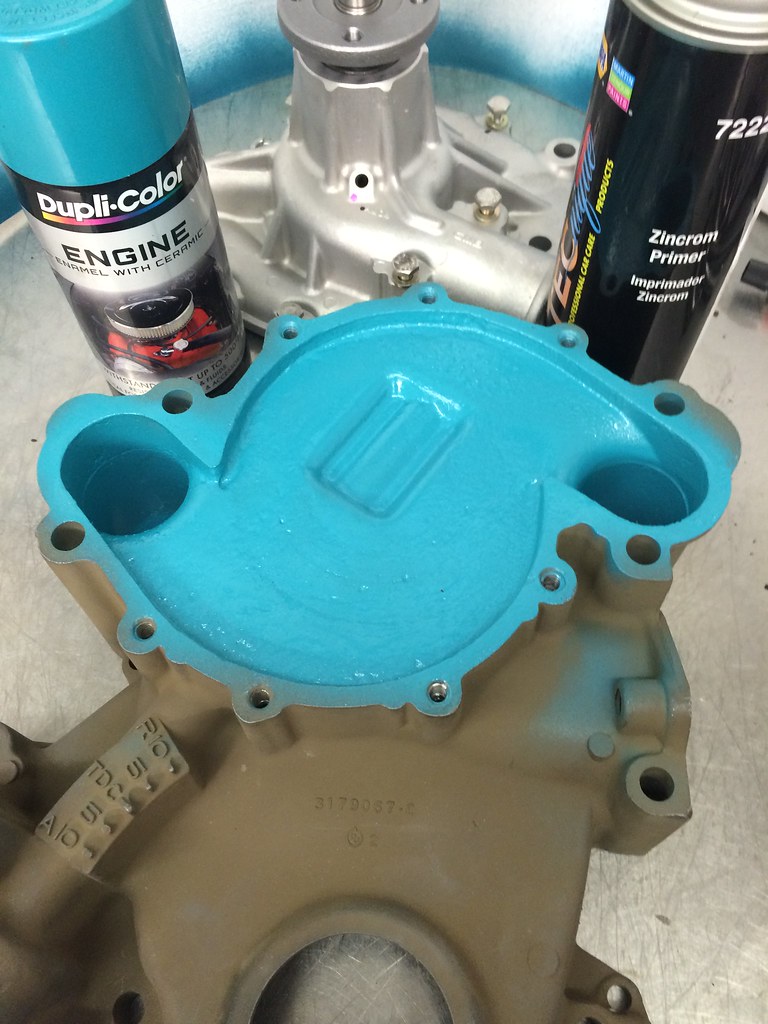

This is more or less a repeat of this build thread but this time, we are using a complete off the shelf 343 rebuild kit from Ebay. This one is for ELRonDeCuba going to France.

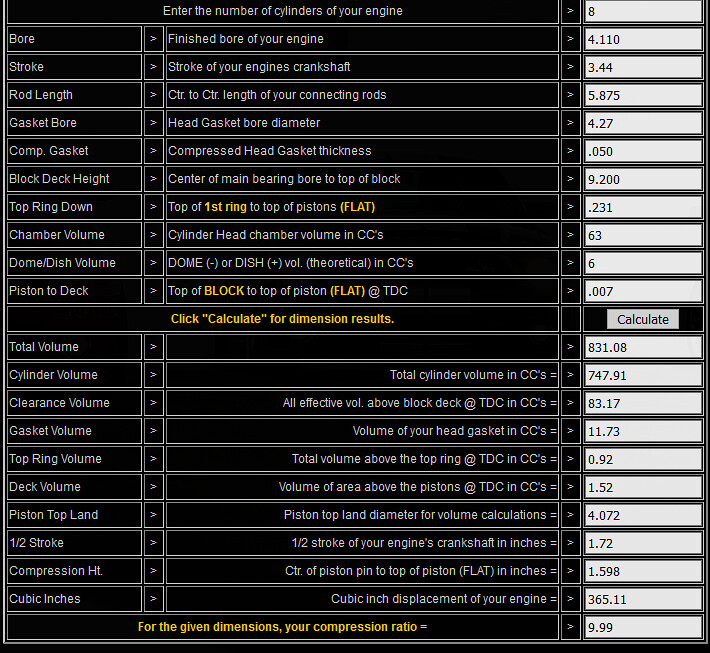

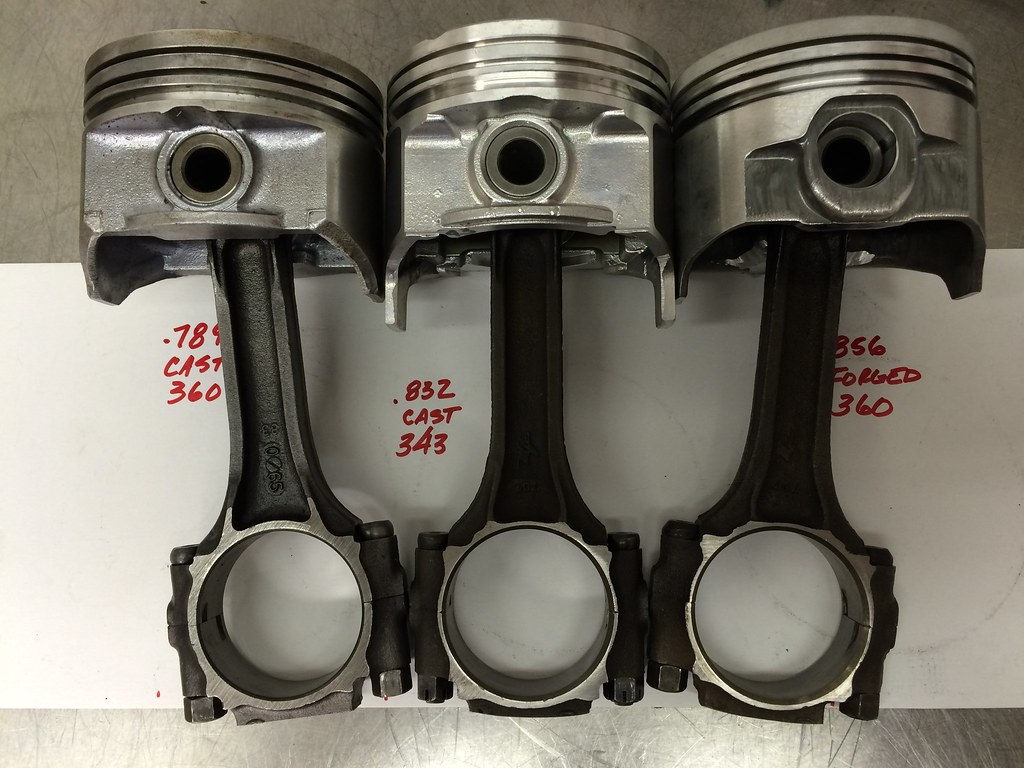

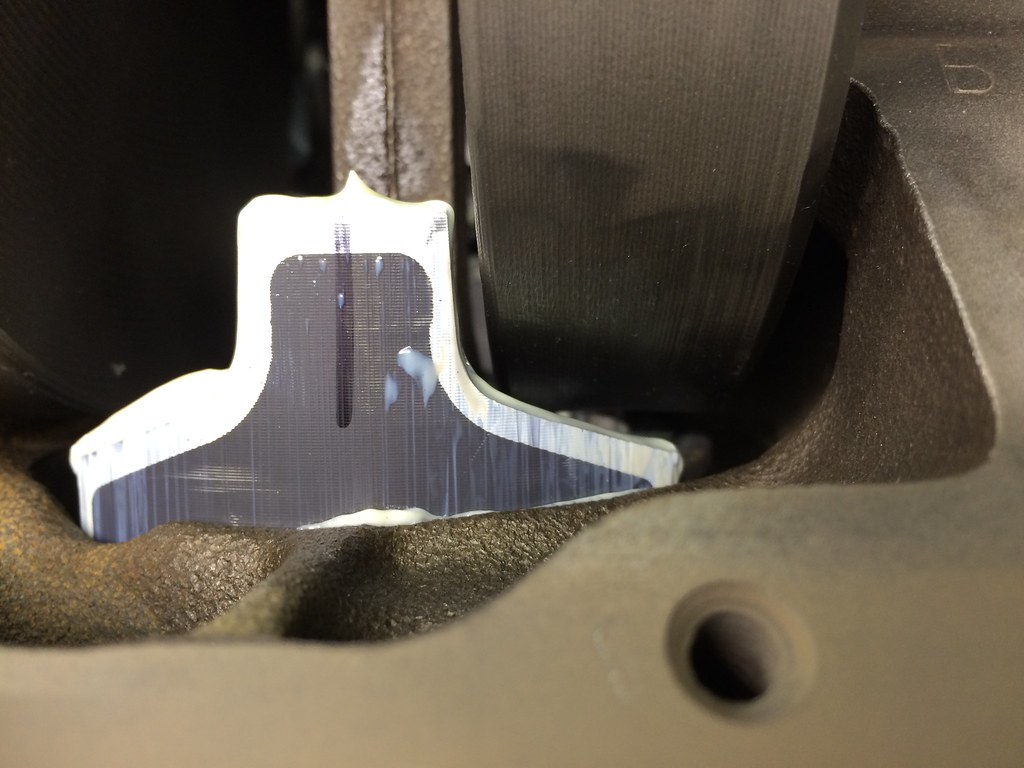

Again, the idea is to use off the shelf 343 flat top pistons to boost the compression ratio just below the magical number of 10.0:1 to be able to run on regular old pump gas.

This is the kit that I bought off of Ebay.

This the actual kit.

IMG_0813 by Rick Jones, on Flickr

IMG_0813 by Rick Jones, on Flickr

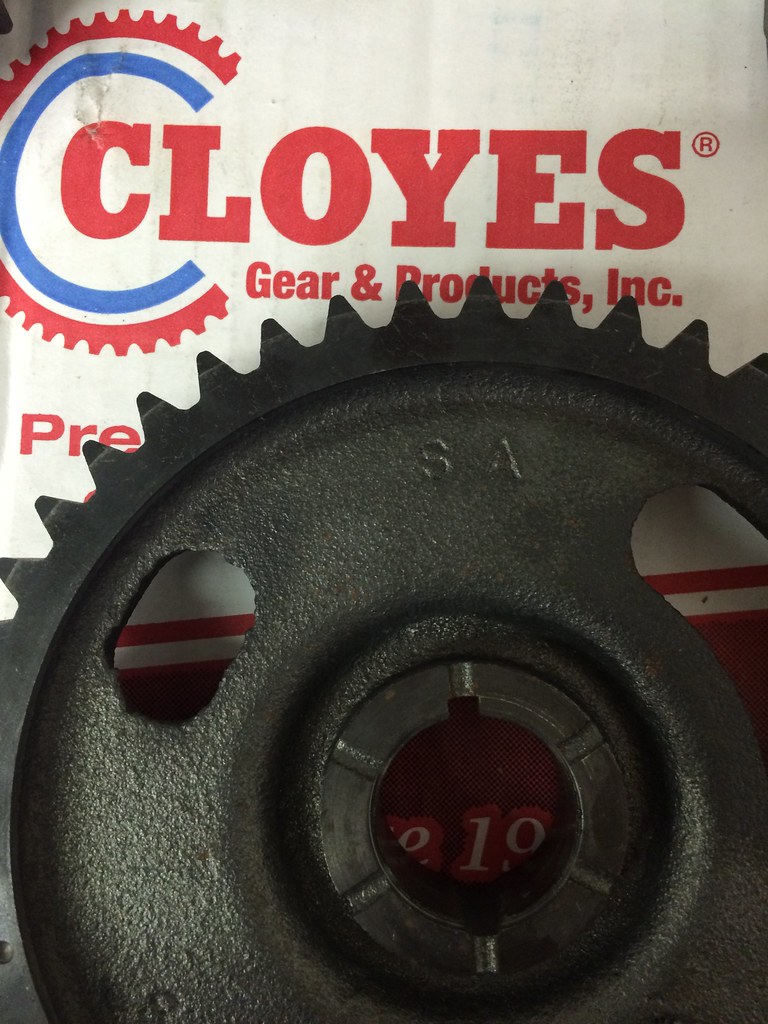

The cam card.

IMG_0814 by Rick Jones, on Flickr

IMG_0814 by Rick Jones, on Flickr

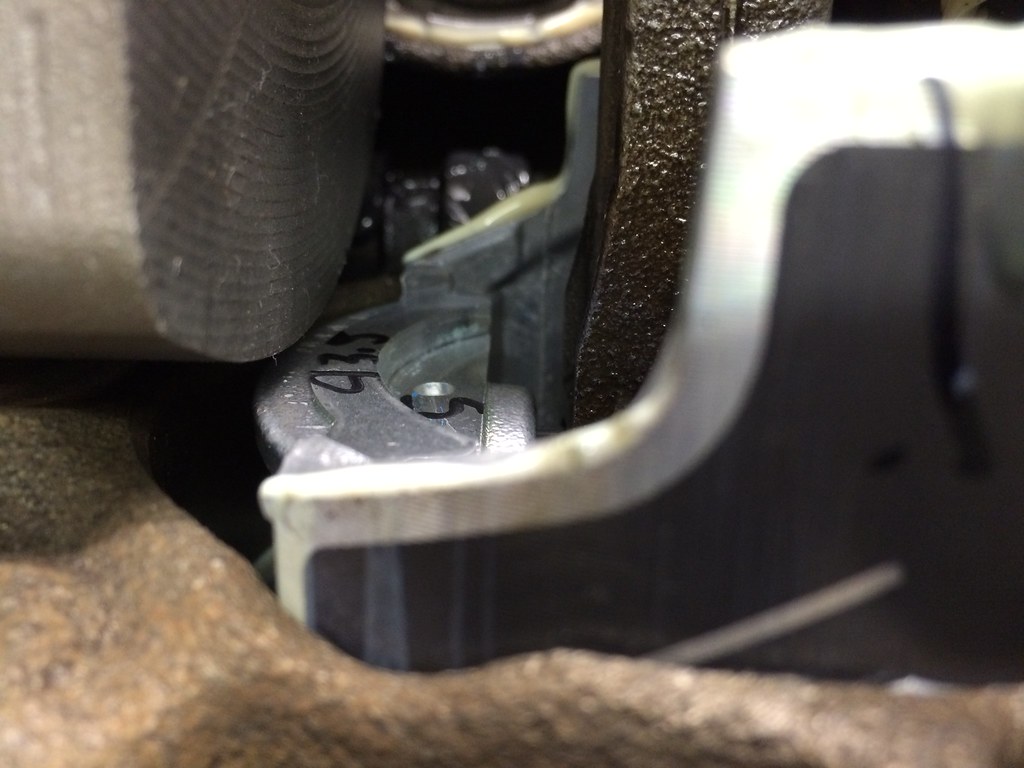

The first key things that I had to do before ordering the kit was:

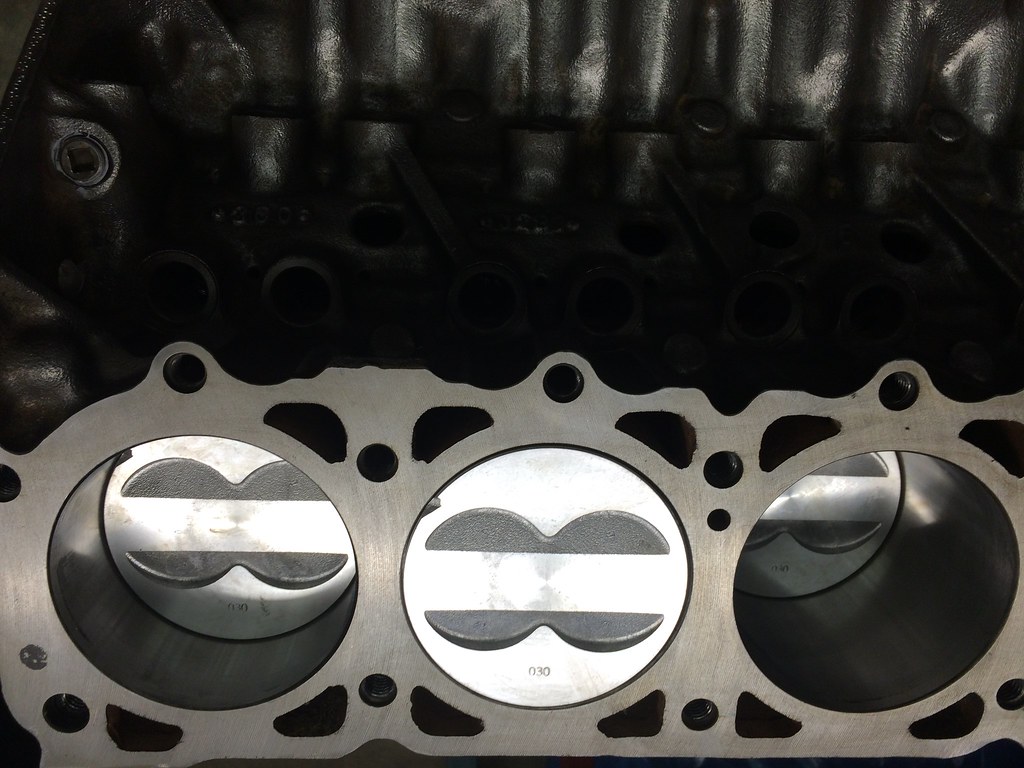

1. Select a pair of cylinder heads with the largest combustion chamber (63cc) so that I can keep the compression ratio below 10.0:1. I found a set of cylinder heads casted from 1978 that have the 63cc combustion chamber. They vary quite a bit from year to year and must be checked to make sure of the chamber size.

2. Determine what over size pistons were needed.

3. Determine what under size Rod and Main Bearings were needed.

Again, the idea is to use off the shelf 343 flat top pistons to boost the compression ratio just below the magical number of 10.0:1 to be able to run on regular old pump gas.

This is the kit that I bought off of Ebay.

This the actual kit.

IMG_0813 by Rick Jones, on Flickr

IMG_0813 by Rick Jones, on FlickrThe cam card.

IMG_0814 by Rick Jones, on Flickr

IMG_0814 by Rick Jones, on FlickrThe first key things that I had to do before ordering the kit was:

1. Select a pair of cylinder heads with the largest combustion chamber (63cc) so that I can keep the compression ratio below 10.0:1. I found a set of cylinder heads casted from 1978 that have the 63cc combustion chamber. They vary quite a bit from year to year and must be checked to make sure of the chamber size.

2. Determine what over size pistons were needed.

3. Determine what under size Rod and Main Bearings were needed.

Comment