Spent a good portion of last night and about 5 minutes this morning working on my gauge cluster. Figured I would do a little walk through, since I couldn't find one and went into it blind (let me know if I did something wrong, missed something, etc.) Also, just a note: I disassembled two clusters and used the best parts from each. Just in case I mention that in the walkthrough, so it won't be confusing later on.

What you'll need:

Needle nose pliers

Flat head screwdriver

Philips head screwdriver

Very fine steel wool

Model paint (in the colors that you need to touch up)

-I used Model Master flourescent red and gloss white and Testors red and dark blue

Set of very small brushes (I used only a 10/0 and a 5/0)

-They don't need to be expensive brushes, but make sure they are quality enough to hold up for detail work

Invisible Glass (or other glass cleaner)

Deep well 3/8" socket - a regular one works fine, but I suggest deep well so you can turn it by hand. However, you can use a regular 3/8" socket with no issue.

Paper towels

Power Drill

Drill (bit) set

Small torx bit (depending on year)

Toothpicks

Cotton swabs

Isopropyl alcohol

Emblem adhesive (or any other strong, long-lasting adhesive)

-I used 3M emblem and badge adhesive

Inverted voltmeter

-Sunpro CP7985 works well

Trashcan

Common sense

Gauge cluster in need of some love

So, lets get started shall we?

Removal:

First things first, we need to remove the gauge cluster from the vehicle (if it is not already out). Simply reach under your dash and disconnect all the connectors and bulbs, then disconnnect your speedometer. It should slide out relatively easily (you may want to lay something over the steering column to protect the paint just in case). Be gentle with it--it really does not require much force to get out, you just have to find the right spot.

Disassembly:

Now what we will need to do, is begin disassembly. Make sure you keep track of you screws, nuts, bolts, etc, etc. However you have found best to keep up with them will work just fine. But, if you absolutely must follow this to a tee, I cut out a piece of cardboard in the shape of the cluster, then poke holes with scissors in the spots where there are screws. Next, I just poke them into their respective holes. This way I know exactly which screw goes where.

Moving on, you will find three screws on the bottom of the circuit board and three on top. You will also find five screws around the perimeter of the AC controls. These all need to be removed. Next, pull the AC controls out (the knob on the temperature switch pulls off, make sure you remove it before removing the rest of the assembly). Next, remove the remaining gauge cluster assembly. Set the case and AC controls aside for now.

Now we will disassemble the gauge cluster assembly. Looking at the back you will notice four studs coming through on the left, and five on the right--these are your gauges (except for your speedometer/odometer, that is the giant silver thing in the middle). If you flip the gauge cluster over, you will notice that your oil/amp and fuel/temp cover plates are held on by either a small hex head or torx head bolt. I did not have the proper size to remove the hex head with a socket, so I just grabbed onto it with needle nose pliers and twisted--they aren't torqued very tight, so this was not an issue. If yours is the torx style, then simply use the proper torx bit, or follow the previous advice if you don't have it.

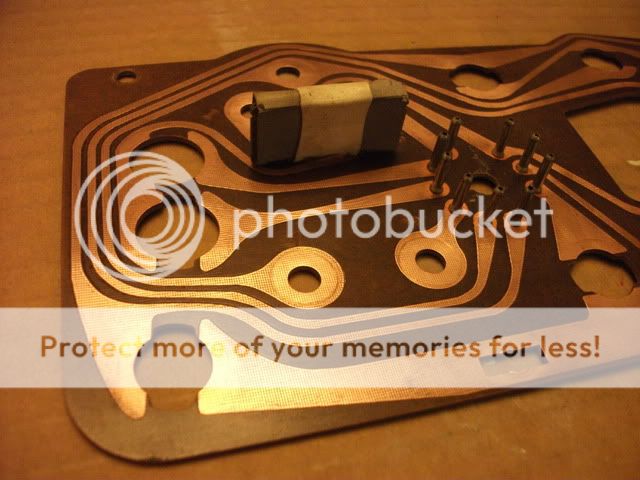

After the cover plates are off, turn the unit back over and remove the nuts (use the 3/8" deep well socket if they are to tight to hand remove) that hold the four outside gauges on (as noted above). The gauges should slide out without a hitch; set them aside. At this point, the oil/amp side of the metal plate between the circuit board and shell of cluster should come off--set it aside as well. Next, we will remove the speedometer assembly.

Simply unscrew the two screws on the metal casing that is sticking up out of the center of the circuit board--this will release the speedometer. Set it aside as well.

The unit should be fully disassembled at this point.

What you'll need:

Needle nose pliers

Flat head screwdriver

Philips head screwdriver

Very fine steel wool

Model paint (in the colors that you need to touch up)

-I used Model Master flourescent red and gloss white and Testors red and dark blue

Set of very small brushes (I used only a 10/0 and a 5/0)

-They don't need to be expensive brushes, but make sure they are quality enough to hold up for detail work

Invisible Glass (or other glass cleaner)

Deep well 3/8" socket - a regular one works fine, but I suggest deep well so you can turn it by hand. However, you can use a regular 3/8" socket with no issue.

Paper towels

Power Drill

Drill (bit) set

Small torx bit (depending on year)

Toothpicks

Cotton swabs

Isopropyl alcohol

Emblem adhesive (or any other strong, long-lasting adhesive)

-I used 3M emblem and badge adhesive

Inverted voltmeter

-Sunpro CP7985 works well

Trashcan

Common sense

Gauge cluster in need of some love

So, lets get started shall we?

Removal:

First things first, we need to remove the gauge cluster from the vehicle (if it is not already out). Simply reach under your dash and disconnect all the connectors and bulbs, then disconnnect your speedometer. It should slide out relatively easily (you may want to lay something over the steering column to protect the paint just in case). Be gentle with it--it really does not require much force to get out, you just have to find the right spot.

Disassembly:

Now what we will need to do, is begin disassembly. Make sure you keep track of you screws, nuts, bolts, etc, etc. However you have found best to keep up with them will work just fine. But, if you absolutely must follow this to a tee, I cut out a piece of cardboard in the shape of the cluster, then poke holes with scissors in the spots where there are screws. Next, I just poke them into their respective holes. This way I know exactly which screw goes where.

Moving on, you will find three screws on the bottom of the circuit board and three on top. You will also find five screws around the perimeter of the AC controls. These all need to be removed. Next, pull the AC controls out (the knob on the temperature switch pulls off, make sure you remove it before removing the rest of the assembly). Next, remove the remaining gauge cluster assembly. Set the case and AC controls aside for now.

Now we will disassemble the gauge cluster assembly. Looking at the back you will notice four studs coming through on the left, and five on the right--these are your gauges (except for your speedometer/odometer, that is the giant silver thing in the middle). If you flip the gauge cluster over, you will notice that your oil/amp and fuel/temp cover plates are held on by either a small hex head or torx head bolt. I did not have the proper size to remove the hex head with a socket, so I just grabbed onto it with needle nose pliers and twisted--they aren't torqued very tight, so this was not an issue. If yours is the torx style, then simply use the proper torx bit, or follow the previous advice if you don't have it.

After the cover plates are off, turn the unit back over and remove the nuts (use the 3/8" deep well socket if they are to tight to hand remove) that hold the four outside gauges on (as noted above). The gauges should slide out without a hitch; set them aside. At this point, the oil/amp side of the metal plate between the circuit board and shell of cluster should come off--set it aside as well. Next, we will remove the speedometer assembly.

Simply unscrew the two screws on the metal casing that is sticking up out of the center of the circuit board--this will release the speedometer. Set it aside as well.

The unit should be fully disassembled at this point.

.

.

, just be gingerly when cleaning them in the future.

, just be gingerly when cleaning them in the future.

Comment