Hi All.

Figured I'd post pictures at the top of the thread. Because a thread is useless without pictures, right?

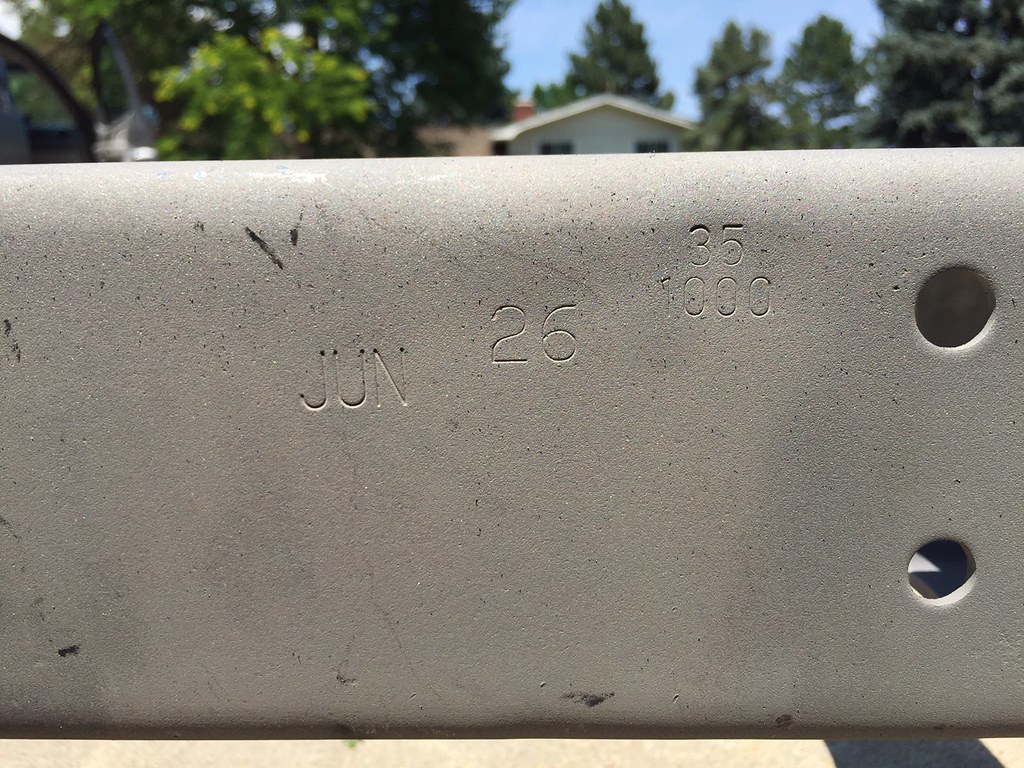

My name is Finn. I'm from Denver. About a year ago, I bought a '70/'71 J-4000 Gladiator. It was built in July 1970, which places it as a '71 model year, but it still had a few Kaiser things left, like Gladiator stickers on the tailgate.

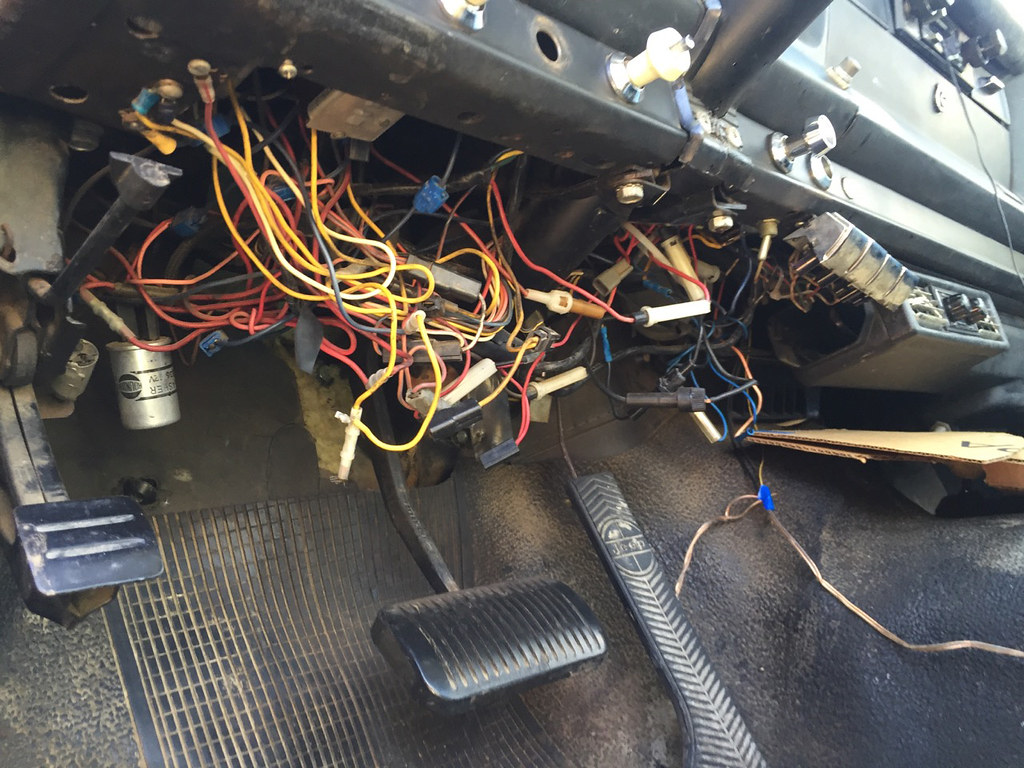

The milage is likely to be only 55,000 -- that's what the previous two owners claimed. The condition of the truck seems to support that. But it also supports that it has been in the Colorado sun for nearly fifty years. Not much was "wrong" with it. It drove, stopped (kinda), played music. I was looking for a DD rig though, and I wanted it to be a little more quiet, comfortable and modern.

I've had my share of DD'ing old factory rigs. I drove a 1967 Jeepster as a DD for three years, and about the only modification it had was lovely zebra carpet.

Don't ya love PO's?

There are some pictures at my first post here:http://www.ifsja.org/forums/vb/showthread.php?t=179622

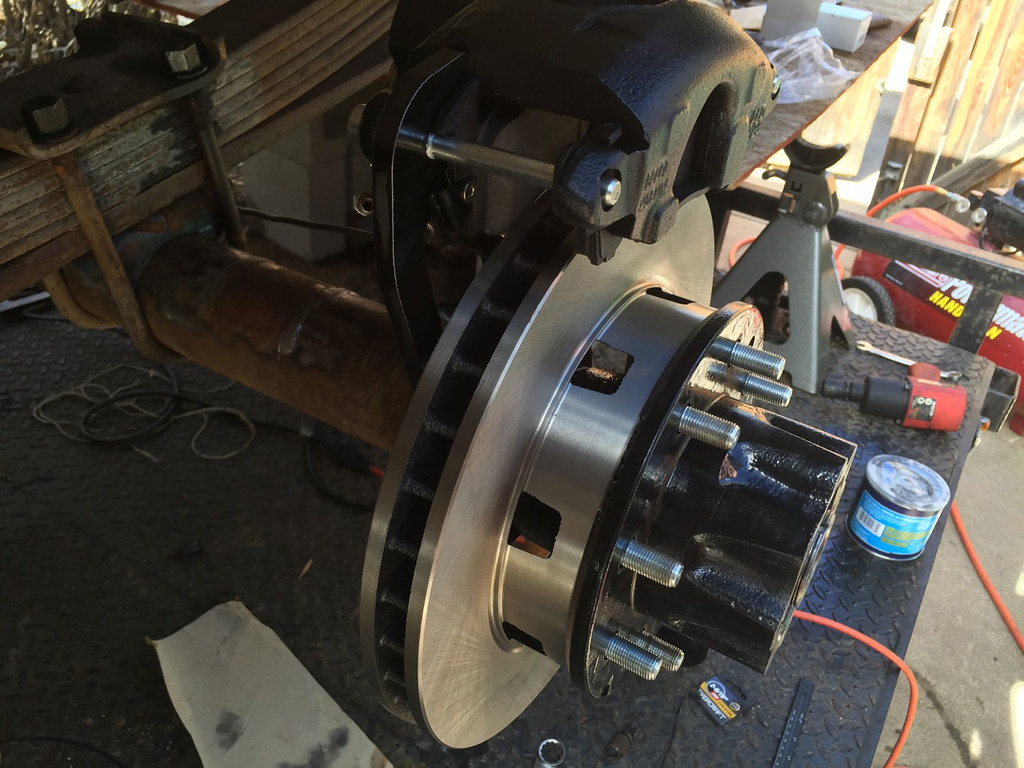

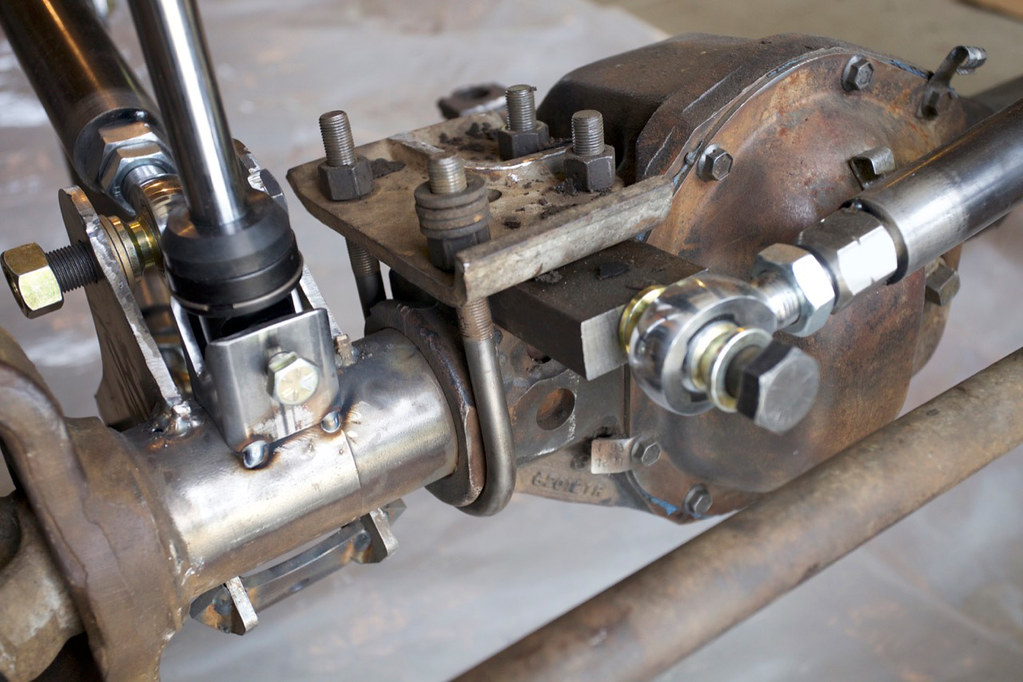

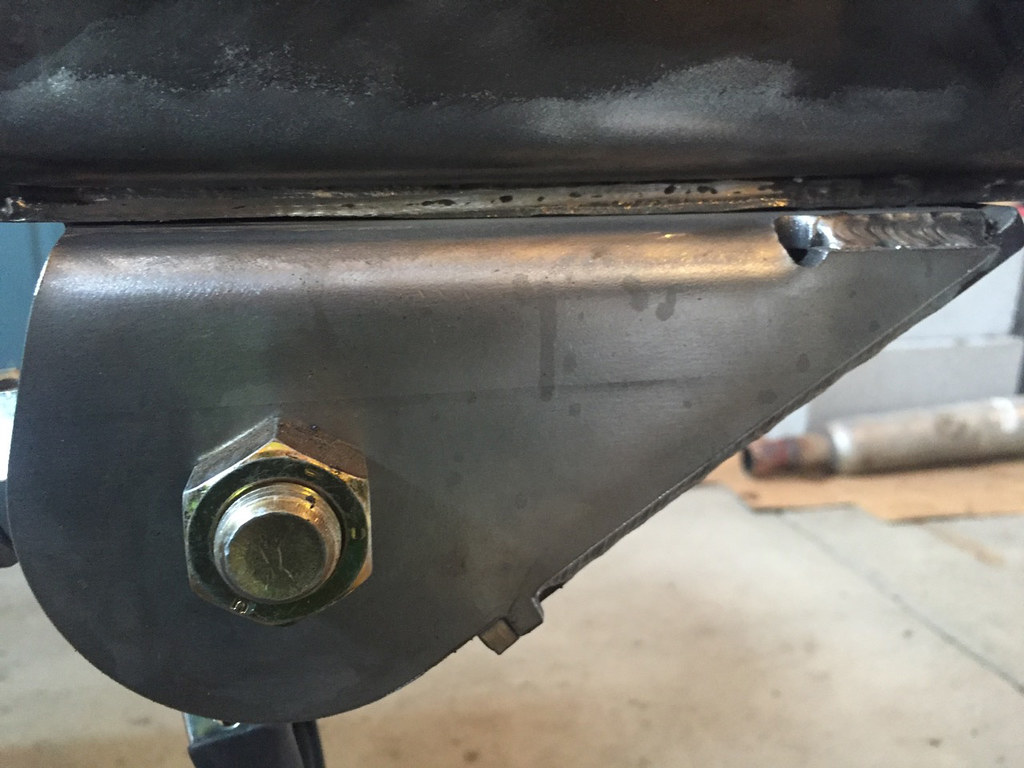

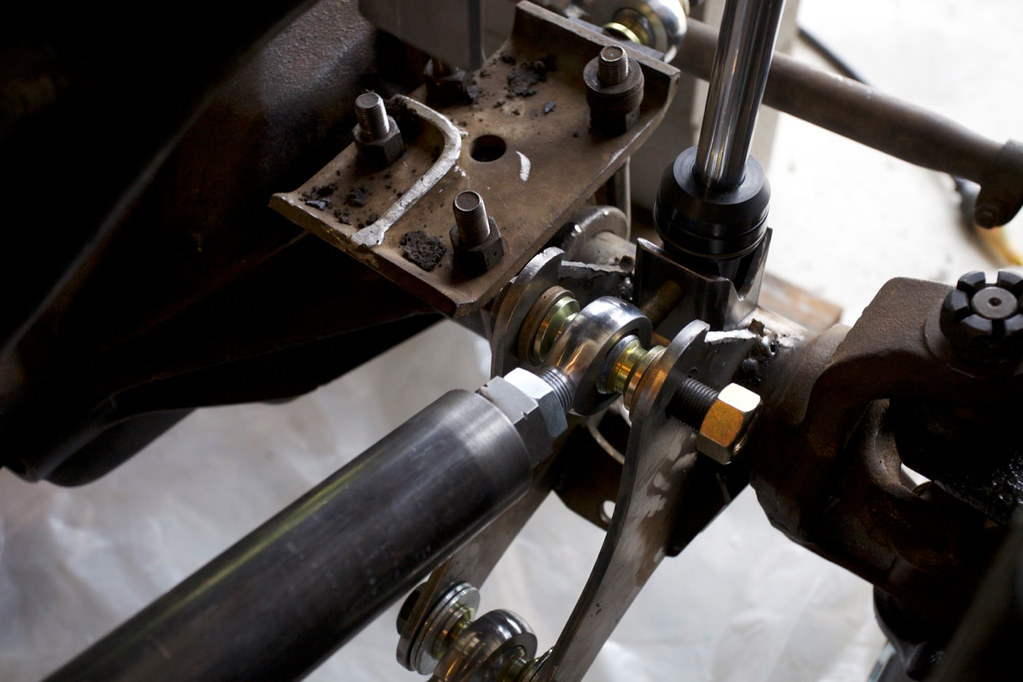

Last July, looking over the truck I justified new axles. I had no problems with a 44 up front and 60 in the rear, they pretty much needed to be rebuilt completely. Pretty much every wear item, and alot of items that shouldn't have been worn, needed replacement. The splines for the Selectro hubs were stripped, and on my truck the front hub is integrated with the drum. So I needed to find good drums with Selectro hub splines. Nope. And it was my understanding that the rear break parts were near impossible to find too. And the rear axle was off center for no reason except for clearing the gas tank. (Yes, Jeep could have engineered it to be easier to clear rocks off-road, but this truck was never intended as a rock crawler.) And, I'm in the mountains a lot, and I really wanted discs. Drums get scary on some of our passes. And three gears in a TH-400 doesn't exactly give you the most options for gearing down. So, I looked into which other (Big Three) trucks have the same axle widths as a FSJ (wide-track only) Only Dodge was close. It was hard to tell what the Jeep's WMS-WMS was, and I forget what I measured. I think factory was about 65". Dodge came in at 67" while Chevy and Ford trucks were 69". So, Dodge it was. However, until '81 I believe, Dodge used a unique front knuckle arrangement with a "unit bearing." Essentially, parts are hard to get -- which is why I was changing axles in the first place. Cool thing is 82-89(maybe more?) have a 34" front frame rail spacing, just like FSJs! So, I went out and got an '85 Dodge W350, non running. When I got home, I found some funky bump on the axle and I got to learn about CAD. Joy. Oh well. Buyer error. IF you're following my path, get an '84-'81. They have real lockouts.

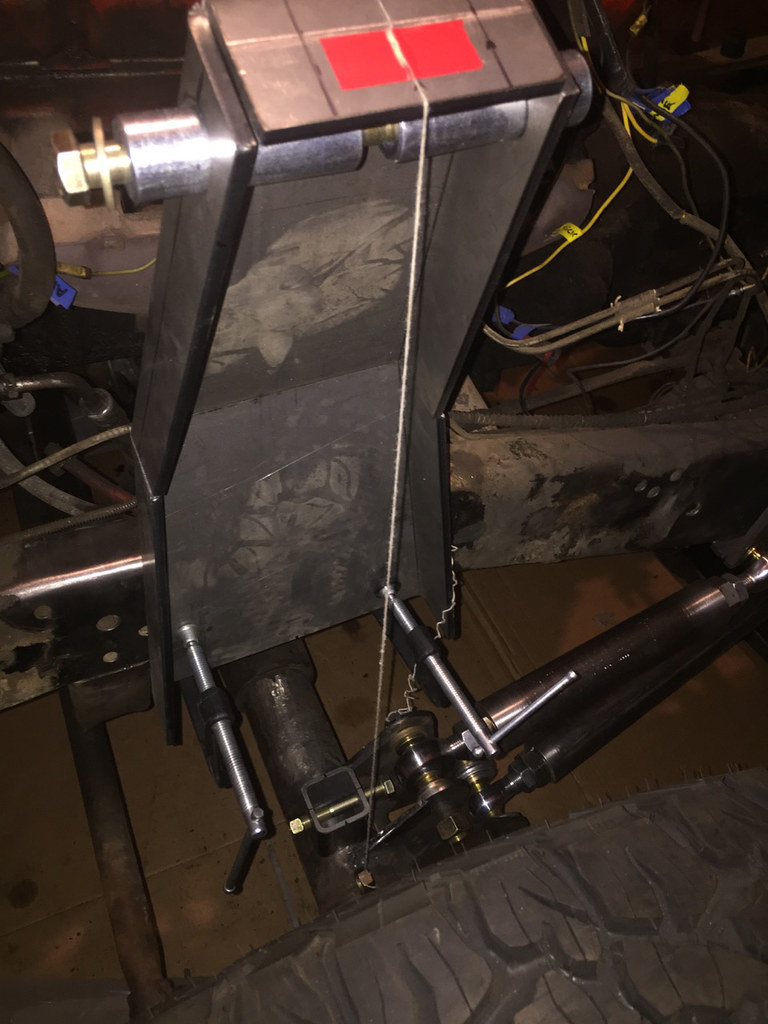

So, the stock Dodge CAD setup is a vacuum control. Vacuum controlled things scare me a lot, and it relied on vacuum switches in the NP208 that I wasn't going to use, so I decided to make it cable operated. There is a product called 4x4 Posi Lock made specifically for this Dodge axle, but at ~$150 I was too cheap. Plus, it has an ugly handle.

I happened to find this writeup of exactly what I wanted to do: http://www.jeepforum.com/forum/f12/h...ite-up-595515/

So, I followed the instructions for the most part, however I decided to remove (rip) the vacuum motor, and control the shift fork from there, as opposed to drilling a hole through the opposite side of the housing. The net result of this is that the writeup gives you a shift handle that is "in" for disengaged 4WD, whereas mine is "out". It was a "prettier" solution to me design wise, so I decided that I could live with the handle "out" most of the time.

Here's what I did.

I'm drilling out the end of the former vacuum motor. Nice jig. I know. It worked.

Thread the same piece. (I don't have a T-handle for taps this big. It's 3/8 NPT I believe)

Drill a hole down through the shift actuator. The fork runs on this shaft.

I also drilled a hole perpendicular to this one for two set screws to hold the inner part of the lock cable into the shaft. It was too small for me to thread.

And ta da. Now it works with a cable.

(Edited whole thread to salvage photos from Photobucket Suicide)

Figured I'd post pictures at the top of the thread. Because a thread is useless without pictures, right?

My name is Finn. I'm from Denver. About a year ago, I bought a '70/'71 J-4000 Gladiator. It was built in July 1970, which places it as a '71 model year, but it still had a few Kaiser things left, like Gladiator stickers on the tailgate.

The milage is likely to be only 55,000 -- that's what the previous two owners claimed. The condition of the truck seems to support that. But it also supports that it has been in the Colorado sun for nearly fifty years. Not much was "wrong" with it. It drove, stopped (kinda), played music. I was looking for a DD rig though, and I wanted it to be a little more quiet, comfortable and modern.

I've had my share of DD'ing old factory rigs. I drove a 1967 Jeepster as a DD for three years, and about the only modification it had was lovely zebra carpet.

Don't ya love PO's?

There are some pictures at my first post here:http://www.ifsja.org/forums/vb/showthread.php?t=179622

Last July, looking over the truck I justified new axles. I had no problems with a 44 up front and 60 in the rear, they pretty much needed to be rebuilt completely. Pretty much every wear item, and alot of items that shouldn't have been worn, needed replacement. The splines for the Selectro hubs were stripped, and on my truck the front hub is integrated with the drum. So I needed to find good drums with Selectro hub splines. Nope. And it was my understanding that the rear break parts were near impossible to find too. And the rear axle was off center for no reason except for clearing the gas tank. (Yes, Jeep could have engineered it to be easier to clear rocks off-road, but this truck was never intended as a rock crawler.) And, I'm in the mountains a lot, and I really wanted discs. Drums get scary on some of our passes. And three gears in a TH-400 doesn't exactly give you the most options for gearing down. So, I looked into which other (Big Three) trucks have the same axle widths as a FSJ (wide-track only) Only Dodge was close. It was hard to tell what the Jeep's WMS-WMS was, and I forget what I measured. I think factory was about 65". Dodge came in at 67" while Chevy and Ford trucks were 69". So, Dodge it was. However, until '81 I believe, Dodge used a unique front knuckle arrangement with a "unit bearing." Essentially, parts are hard to get -- which is why I was changing axles in the first place. Cool thing is 82-89(maybe more?) have a 34" front frame rail spacing, just like FSJs! So, I went out and got an '85 Dodge W350, non running. When I got home, I found some funky bump on the axle and I got to learn about CAD. Joy. Oh well. Buyer error. IF you're following my path, get an '84-'81. They have real lockouts.

So, the stock Dodge CAD setup is a vacuum control. Vacuum controlled things scare me a lot, and it relied on vacuum switches in the NP208 that I wasn't going to use, so I decided to make it cable operated. There is a product called 4x4 Posi Lock made specifically for this Dodge axle, but at ~$150 I was too cheap. Plus, it has an ugly handle.

I happened to find this writeup of exactly what I wanted to do: http://www.jeepforum.com/forum/f12/h...ite-up-595515/

So, I followed the instructions for the most part, however I decided to remove (rip) the vacuum motor, and control the shift fork from there, as opposed to drilling a hole through the opposite side of the housing. The net result of this is that the writeup gives you a shift handle that is "in" for disengaged 4WD, whereas mine is "out". It was a "prettier" solution to me design wise, so I decided that I could live with the handle "out" most of the time.

Here's what I did.

I'm drilling out the end of the former vacuum motor. Nice jig. I know. It worked.

Thread the same piece. (I don't have a T-handle for taps this big. It's 3/8 NPT I believe)

Drill a hole down through the shift actuator. The fork runs on this shaft.

I also drilled a hole perpendicular to this one for two set screws to hold the inner part of the lock cable into the shaft. It was too small for me to thread.

And ta da. Now it works with a cable.

(Edited whole thread to salvage photos from Photobucket Suicide)

Comment