Starting a build thread  .

.

Last summer I had the truck repainted, I did most of the disassembly and reassembly of the trim, panels, bumpers, etc.

Truck Looked good drove a 3-400 miles trouble free.

Then,

Last September I checked to oil, added to the top of the "safe" zone and drove to school.

Lunch hour rolled around and I went to town with my buddies and the lifters began to tick loudly, I put it off as sticky lifter(s).

The tick quieted down a bit and later on after school i began to drive home (i should've checked the oil in hindsight but as It didn't leak and I thought it didn't burn much oil I didn't)

Then It started to knock and that's when we trailered it home.

The truck burnt through the entire sump of oil in a 25 mile trip

So a few months roll past and Dad and I clean up the shop so the truck can stay in the warmth. (It was -10*C outside)

I filled engine with oil finally realizing that it was out of oil, however an engine burning oil like that needed a rebuild either way.

The 327 fired to life and didnt make a single tick, knock, or cough. It speaks to the toughness of the engine, and the truck drove into the shop on its own power.

Later, in January, disassembly began.

Took the whole front clip off to ease the removal of engine plus transmission

Motor is out

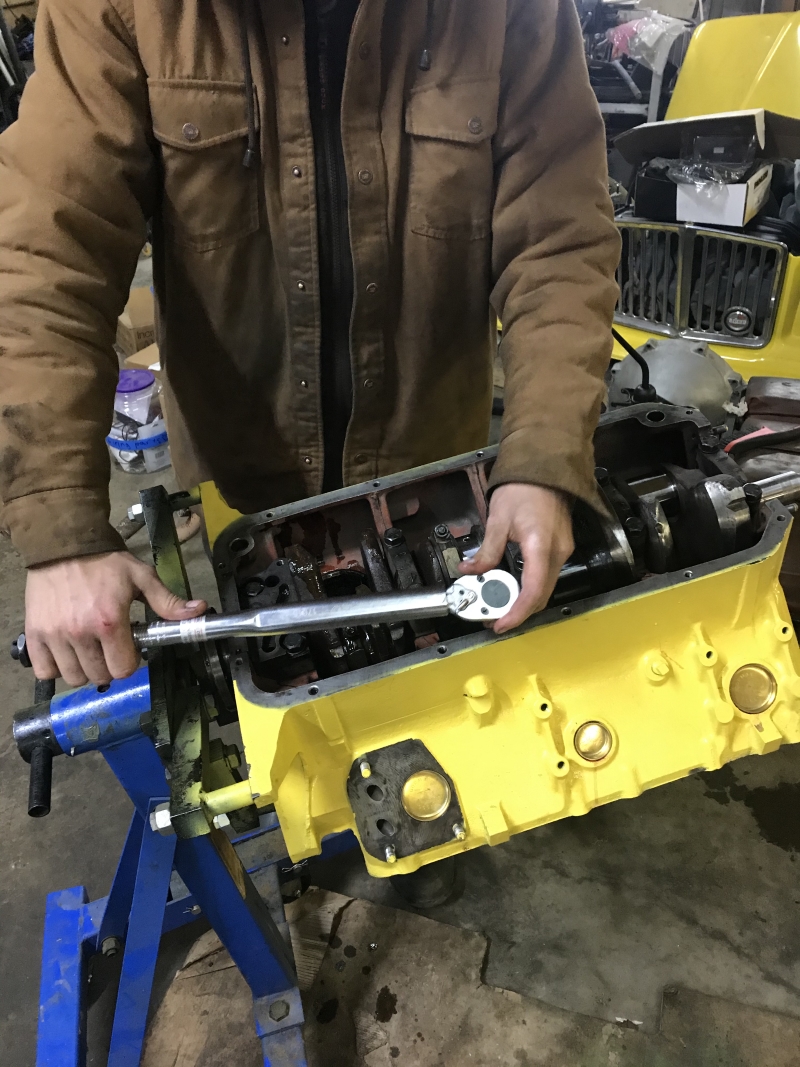

Stripped the engine down with Dad and my very helpful hot rodding neighbor (we are newbies)

I made sure to tag & bag all the bolts and take pictures of as many things as i could.

.

.Last summer I had the truck repainted, I did most of the disassembly and reassembly of the trim, panels, bumpers, etc.

Truck Looked good drove a 3-400 miles trouble free.

Then,

Last September I checked to oil, added to the top of the "safe" zone and drove to school.

Lunch hour rolled around and I went to town with my buddies and the lifters began to tick loudly, I put it off as sticky lifter(s).

The tick quieted down a bit and later on after school i began to drive home (i should've checked the oil in hindsight but as It didn't leak and I thought it didn't burn much oil I didn't)

Then It started to knock and that's when we trailered it home.

The truck burnt through the entire sump of oil in a 25 mile trip

So a few months roll past and Dad and I clean up the shop so the truck can stay in the warmth. (It was -10*C outside)

I filled engine with oil finally realizing that it was out of oil, however an engine burning oil like that needed a rebuild either way.

The 327 fired to life and didnt make a single tick, knock, or cough. It speaks to the toughness of the engine, and the truck drove into the shop on its own power.

Later, in January, disassembly began.

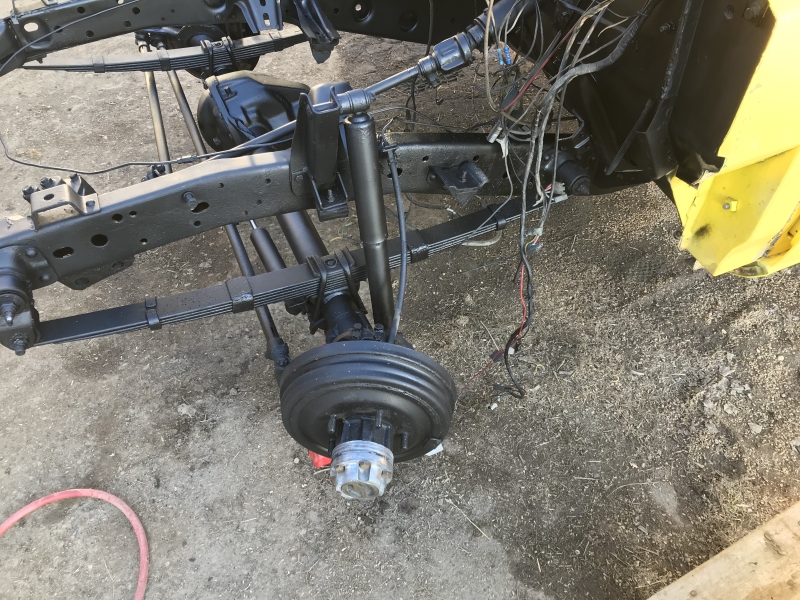

Took the whole front clip off to ease the removal of engine plus transmission

Motor is out

Stripped the engine down with Dad and my very helpful hot rodding neighbor (we are newbies)

I made sure to tag & bag all the bolts and take pictures of as many things as i could.

)

) ) Very nice weather for March in Alberta, so I worked on stripping the frame and firewall of rust and junk and painted them!

) Very nice weather for March in Alberta, so I worked on stripping the frame and firewall of rust and junk and painted them!

.

.

Comment