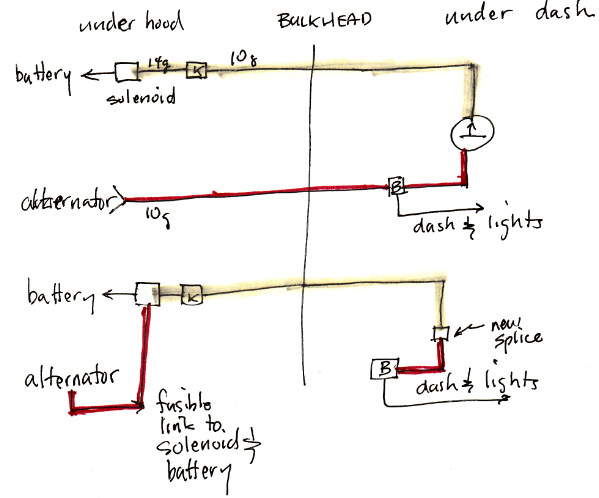

I have redone my instrument cluster and installed a new Voltmeter where the Ammeter was. Trying to prevent a possible fire! I am trying to work out the correct wiring under the dash and at the Alternator. I hooked both the old wires (Yellow and Red) under the dash, to the positive post of the New Voltmeter and Installed a new Ground Wire from the negative post to a good ground under the dash. Now I am trying to figure out how to hook up my Alternator.

Do I leave the old red wire from the alternator connected at the alternator post (making a connection up to the dash Voltmeter) and add a new larger gauge wire to the same alternator post connecting the alternator to the battery? Is that correct?

Maybe I’m over thinking it but I don’t want to blow anything up.

Do I leave the old red wire from the alternator connected at the alternator post (making a connection up to the dash Voltmeter) and add a new larger gauge wire to the same alternator post connecting the alternator to the battery? Is that correct?

Maybe I’m over thinking it but I don’t want to blow anything up.

Comment