Hey guys,

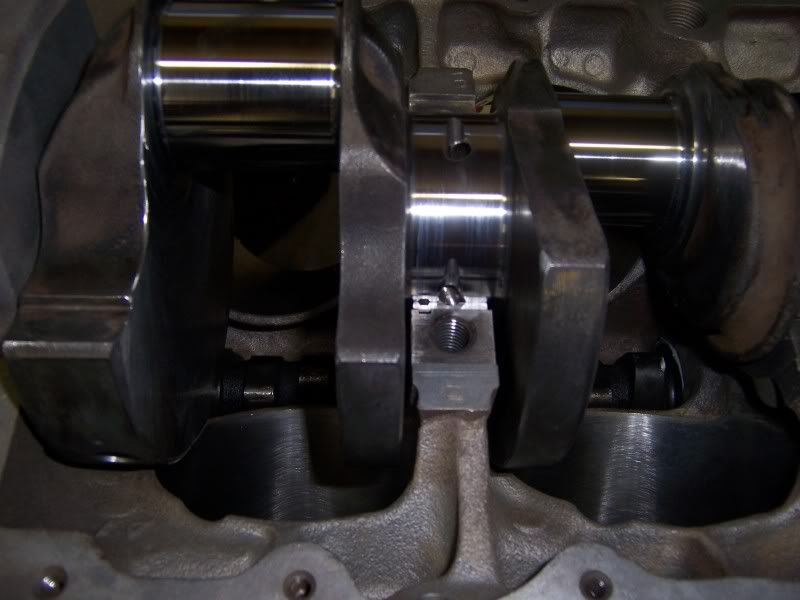

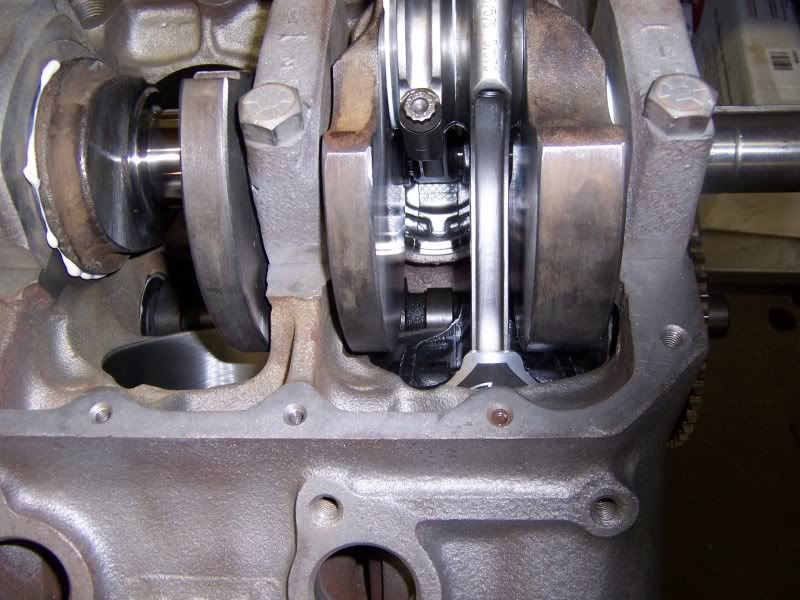

Just another news anouncement ... Rick Jones, who helped build my 304 stroker is now underway on building a budget AMC 360 stroker, which should turn out to be awesome.

I'll post up pics and details soon ...

STAY TUNED!

Just another news anouncement ... Rick Jones, who helped build my 304 stroker is now underway on building a budget AMC 360 stroker, which should turn out to be awesome.

I'll post up pics and details soon ...

STAY TUNED!

I'm currently on the ship so maybe these govt comps are blocking the pics?

I'm currently on the ship so maybe these govt comps are blocking the pics?

Comment